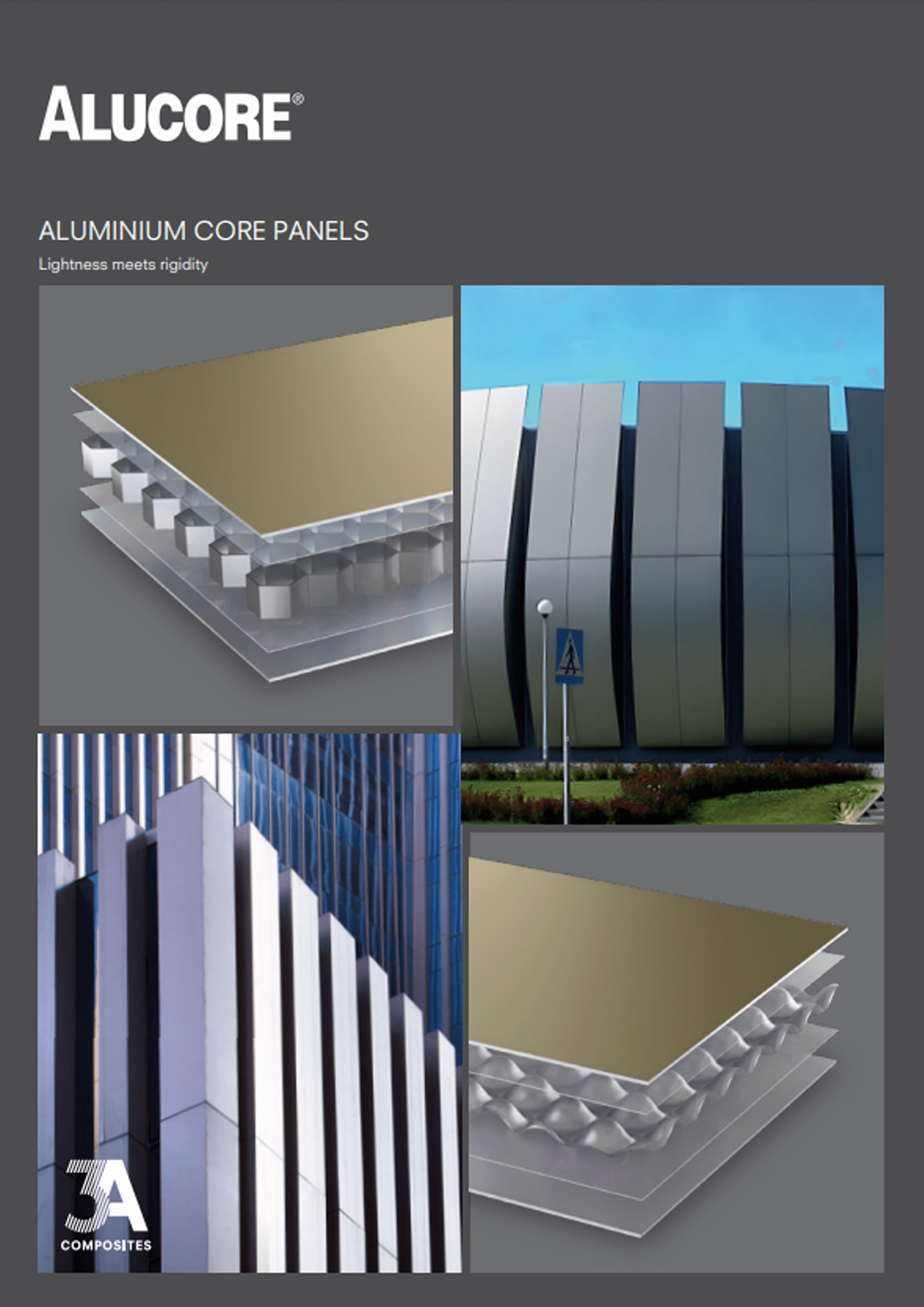

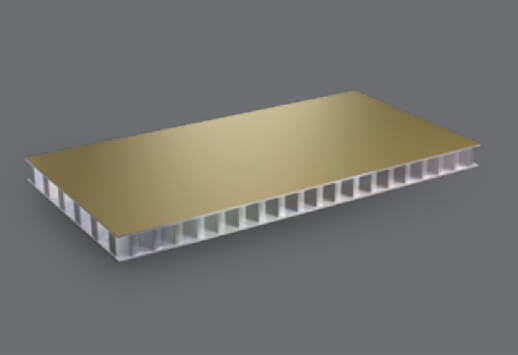

ALUCORE® is an innovative aluminium composite panel consisting of two aluminium cover sheets and a core of aluminium.

ALUCORE® comes in 2 variants ALUCORE® ACCP and ALUCORE® Honeycomb. ALUCORE® features marine grade corrosion resistance alloy 5005 H24 for durability. The PVDF/FEVE coating as per AAMA 2605 ensures long term performance and protection from UV radiation and weathering .

Over lacquering of stove lacquered ALUCORE surfaces of polyester lacquer quality (panels not exposed to weather conditions)

Aluminium treatment and priming carried out at the factory in a continuous process with continuous quality control is advantageous to the over lacquering of the stove lacquered ALUCORE® surface.

ALUCORE® over lacquering procedure:

The composition of lacquer coating for ALUCORE® is basically the same as those for mill finished aluminium surfaces. It is advisable to be familiar with coating systems and materials as well as working methods for aluminium.

- Pre-cleaning of the panels using methylated spirit

- Grinding the surfaces with wet abrasive paper (grain size 360)

- Removing grinding dust with a lint free cloth moistened with spirit

- For the topcoat, please follow the instructions of the topcoat supplier.

- The maximum permissible temperature of the material (ALUCORE® panels) must not exceed 70°C when applying fast-drying methods. During the drying process at high temperatures the ALUCORE® panels must be positioned or stored with great care to prevent deforming.

- ALUCORE® cut edges should not be in contact with organic solvents for a prolonged period of time to avoid weakening the bond.

- ALUCORE® panels lacquered or over lacquered at a later stage should not be bent or folded. The lacquer in the bends or folds may be damaged due to the low elasticity of the topcoat.