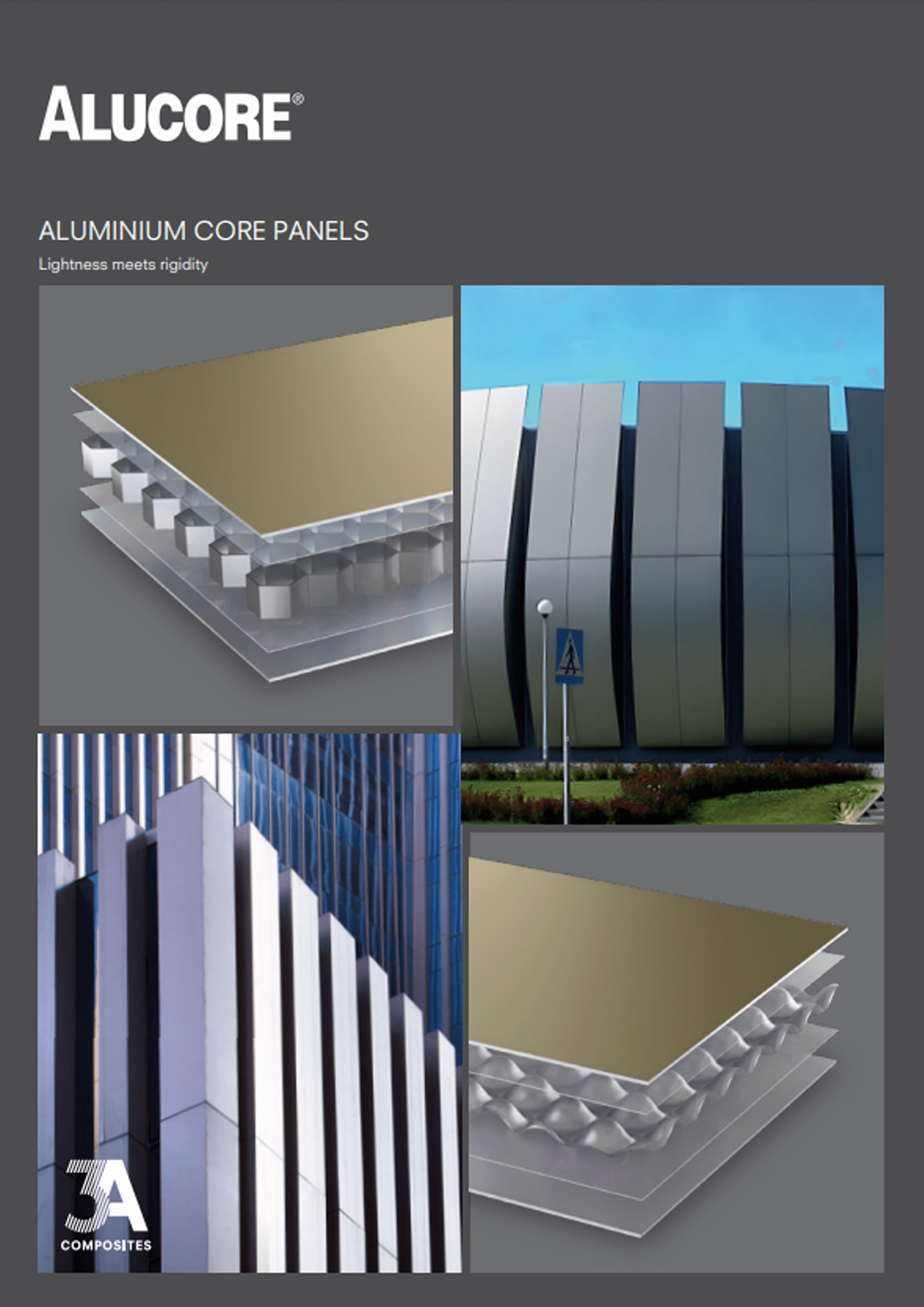

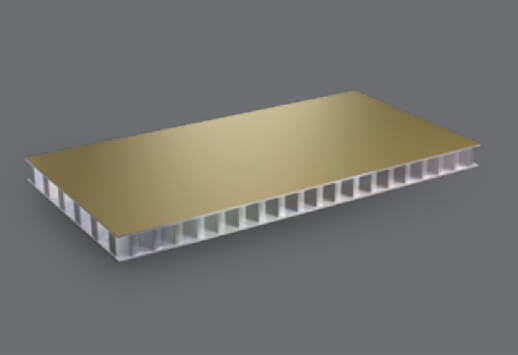

ALUCORE® is an innovative aluminium composite panel consisting of two aluminium cover sheets and a core of aluminium.

ALUCORE® comes in 2 variants ALUCORE® ACCP and ALUCORE® Honeycomb. ALUCORE® features marine grade corrosion resistance alloy 5005 H24 for durability. The PVDF/FEVE coating as per AAMA 2605 ensures long term performance and protection from UV radiation and weathering .

ALUCORE® can be drilled using twist drills normally used for aluminium and plastics on machines common for metals.

- Drill material: high-speed steel (HSS)

- Tool geometry: lip angle: 100° – 140°

- Drilling without burr is possible using the following drills: Spot facing cutter with centre-point.

- Angle of twist: 30° – 45° e.g. Extreme 2TM HSS-G metal drill DIN 338 of De WALT, Idstein, Germany.