Non Combustible Aluminium Composite Panels

ACROSS THE WORLD, ALUCOBOND® A2 is the only non-combustible aluminum composite panel used in architecture.

Due to its non-combustible core and Class A2 fire rating, this fantastic product meets stringent fire regulations and hugely increases the possibilities when it comes to creative building design. It is highly preferred for wall cladding and other facade applications where both safety and aesthetics are crucial.

As with all ALUCOBOND panels, ALUCOBOND® A2 allows for simple processing, is impact-resistant, break-proof, and weatherproof, and above all, non-combustible.

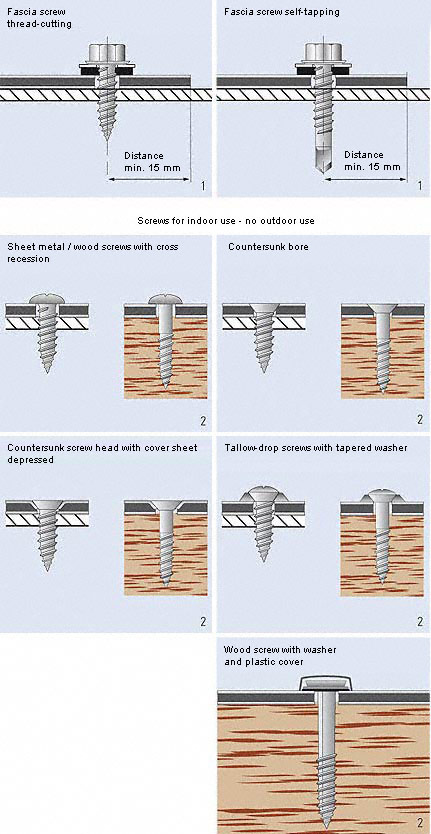

Threaded fasteners for outdoor use

Threaded fasteners for indoor use

Frequently Asked Questions about ALUCOBOND® A2

What is ALUCOBOND® A2?

ALUCOBOND® A2 is a premium grade of aluminium composite panels created for projects where non-combustible facades are essential. It is made by combining two thin aluminium sheets with a mineral-filled core, ensuring excellent fire safety, long-lasting durability, and creative design possibilities for modern buildings.

How is ALUCOBOND® A2 different from standard aluminium composite panels?

Most regular aluminium composite panels use a polyethene core, which can be less fire safe. ALUCOBOND® A2, on the other hand, uses a mineral-based core that does not burn. This makes it a safer option for high-rise buildings and public spaces, while still offering the same lightweight strength and flexibility as traditional ACPs.

What makes ALUCOBOND® A2 non-combustible?

The secret lies in its mineral-filled inorganic core. Unlike cores that catch fire, this material does not ignite or spread flames. That’s why ALUCOBOND® A2 aluminium composite panels meet some of the toughest fire safety standards worldwide.

What certifications or fire safety standards does ALUCOBOND® A2 meet?

ALUCOBOND® A2 aluminium composite panels are tested to EN 13501-1 and are classified as A2-s1, d0, which means they are non-combustible. They also meet international fire safety standards, giving architects and builders confidence when choosing them for safer façade solutions.

What are the main benefits of choosing ALUCOBOND® A2 for construction projects?

By choosing ALUCOBOND® A2 aluminium composite panels, you get the best of both worlds—maximum fire safety along with stunning design options. They are lightweight yet strong, resistant to harsh weather, easy to shape, and available in a wide variety of colours and finishes.

How easy is it to process and install ALUCOBOND® A2 panels?

Working with ALUCOBOND® A2 aluminium composite panels is straightforward. They can be cut, bent, or shaped using common tools like saws or routers. Installation is also flexible, fitting into different façade systems, and their lightweight nature makes handling and transport much easier.

What kind of maintenance does ALUCOBOND® A2 require?

These panels are designed to be low maintenance. A simple wash with water or mild detergent is usually all it takes to keep them looking new. Thanks to their strong resistance to weather and corrosion, ALUCOBOND® A2 aluminium composite panels stay attractive for decades.

What thicknesses and panel sizes are available in ALUCOBOND® A2?

ALUCOBOND® A2 aluminium composite panels come in thicknesses ranging from 3mm to 6mm. Standard widths include 1000mm, 1250mm, and 1500mm, with lengths available up to 6000mm. This variety makes it easy to find the right fit for any architectural project.

How long is the expected lifespan of ALUCOBOND® A2 panels?

When installed correctly and cared for, ALUCOBOND® A2 aluminium composite panels can last more than 30 years. They withstand UV rays, corrosion, and extreme weather, making them a reliable and cost-effective choice for long-term building façades.

Can ALUCOBOND® A2 panels be customized?

Yes, ALUCOBOND® A2 aluminium composite panels are available in many colours and finishes, including metallic, solid, natural, and textured looks. They can also be shaped and fabricated to match unique architectural designs, giving architects complete creative freedom.