As operational energy standards become more stringent, the architectural facade has evolved into a critical environmental performance element rather than a purely aesthetic skin. Among passive design techniques, solar control remains the most influential parameter in reducing internal heat gains, particularly in high-irradiance climates. When integrated with orientation-led planning and thermally efficient envelopes, shading significantly decreases cooling energy demand and enhances occupant comfort.

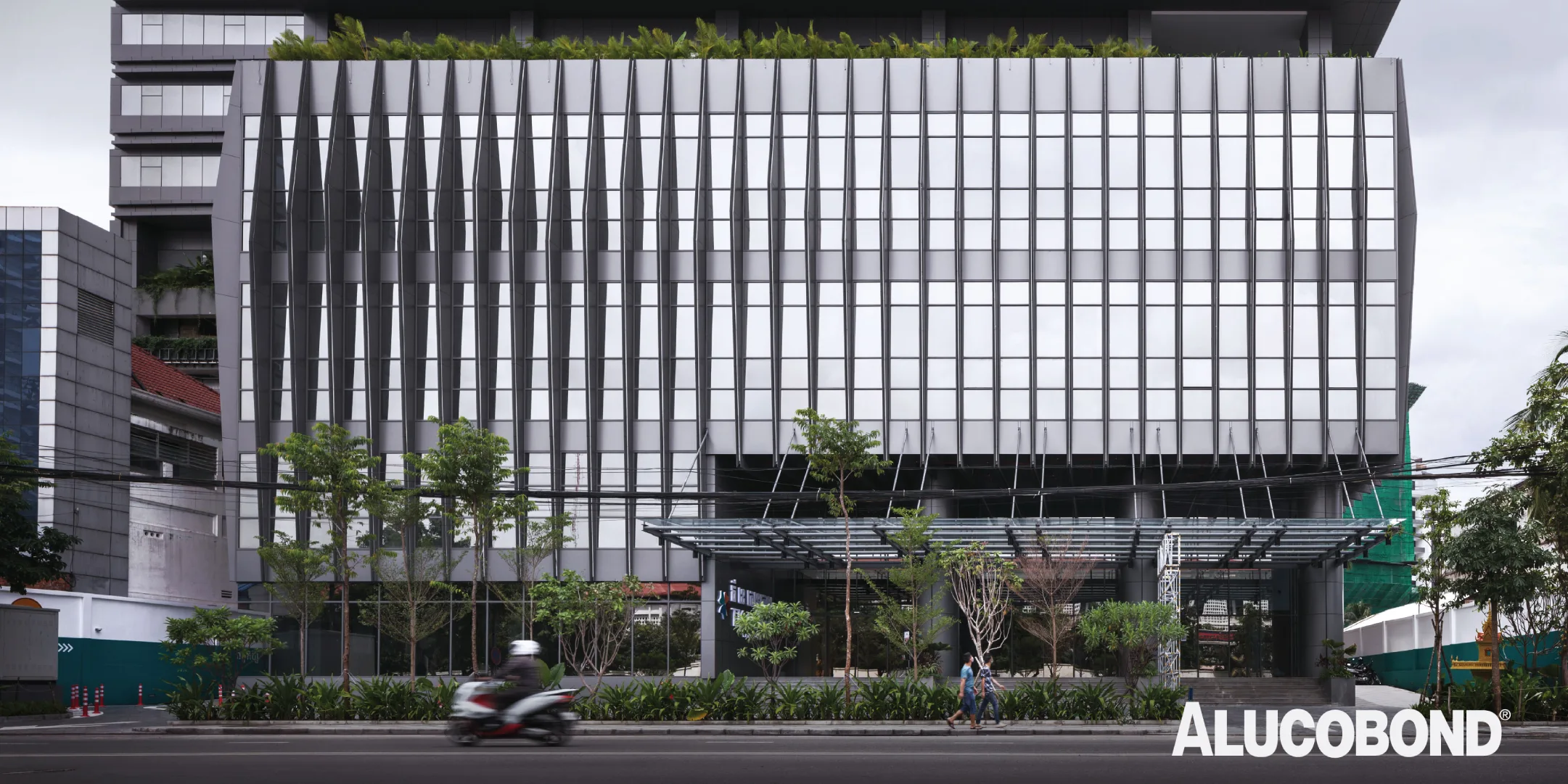

This article provides a technical overview of how contemporary facade engineering uses solar control, orientation and material intelligence to achieve measurable performance outcomes. It also introduces the ALUCOBOND® Solar Shading Software Service, an analytical tool that supports precise, climate-responsive facade design.

Solar Shading: The Primary Passive Strategy for Energy Reduction

Direct solar radiation is one of the important contributors to thermal loads on glazed facades. Minimising this radiation before it reaches the building envelope is the most effective way to reduce mechanical cooling requirements.

Architects and facade engineers use shading fins, perforated panels, overhangs and hybrid screening systems to reduce incident radiation while maintaining visual comfort and daylight levels. Well-engineered shading systems decrease cooling energy consumption, optimise daylight penetration, minimise glare and stabilise indoor temperatures and reduce HVAC cycling.

Shading is therefore essential to performance-driven facade strategies, whether integrated into commercial towers, educational campuses or residential projects.

Key performance benefits of solar shading systems include:

- Reduced cooling energy consumption

- Optimised daylight penetration with controlled glare

- Stabilised indoor thermal conditions

- Reduced HVAC cycling and operational load

Orientation: The Foundation of Responsive Facade Engineering

Orientation determines the intensity, angle and duration of solar exposure. It therefore forms the baseline for any shading strategy.

- East facades require shading for low-morning sun.

- West facades need deeper or closely spaced fins due to sustained afternoon heat.

- South facades in equatorial conditions benefit from pronounced horizontal shading.

- North facades generally require minimal shading but can benefit from controlled daylighting.

Early-stage simulations influence glazing ratios, facade recesses, shading projections and even substructure load calculations. Architects now rely on solar mapping tools during conceptual studies to evaluate the practicality of various building facade design ideas and ensure they align with environmental performance goals.

High-Performance Envelopes: Enhancing Fabric Efficiency

Shading alone cannot deliver optimal performance unless paired with a thermally efficient envelope. Aluminium composite materials such as ALUCOBOND®, ALUCORE® ACCP & Honeycomb and ALUCODUAL® are designed to provide the stiffness, dimensional accuracy and durability required for both cladding and shading components.

Their benefits include:

- Lightweight construction, reducing load on the primary structure

- Resistance to thermal bowing and environmental degradation

- Superior flatness for precision facade alignment

- Long-term performance across diverse climatic conditions

These characteristics make them suitable not only for newly built structures but also for facade re-modelling ideas in projects where weight, access and installation complexity are key considerations.

Material systems for high-performance solar shading

ALUCOBOND® offers a comprehensive suite of engineered materials that can be configured into high-performance solar shading systems. These include ALUCOBOND® PLUS (Fire Retardant Variant), ALUCOBOND® A2 (Non-combustible Core), ALUCORE® ACCP (Aluminium Corrugated Core Panels) & ALUCORE® Honeycomb (Honeycomb core) and ALUCODUAL® (Engineered Solid Sheet), each designed to deliver the structural and environmental resilience required for facade applications.

These material systems offer:

- High rigidity-to-weight ratios, essential for shading fins and extended shading elements.

- Excellent weather and UV resistance, critical for components exposed continuously to solar load.

- Dimensional stability, ensuring fins and screens maintain precision over years of operation.

- Design adaptability, supporting a wide range of shading geometries often employed in contemporary building facade design ideas.

Their mechanical strength and lightness make them ideal for vertical louvres, horizontal overhangs, perforated screens and complex parametric shading assemblies used in performance-driven facades.

Finishes, Surface Technologies and Aesthetic Flexibility

To meet both environmental and aesthetic requirements, 3A Composites materials are available in an extensive collection of finishes:

- Metallic

- Solid architectural colours

- Natural stone aesthetics

- Wood textures

- Anodized-look surfaces

- Glossy muted tones of pastels

All materials are coated with high-performance PVDF/FEVE coil-coating systems, meeting AAMA 2605 performance specifications and ECCA standards. These coatings deliver:

- Exceptional UV resistance

- Long-term colour fidelity

- Chemical resistance

- Low maintenance requirements

This breadth of finishes enables architects to integrate shading seamlessly into the envelope, whether the facade expression is minimalistic, parametric or inspired by biophilic facade design principles.

ALUCOBOND® Solar Shading Software Service: Precision through Simulation

To support data-driven decision-making, ALUCOBOND® offers a specialised Solar Shading Software Service that provides project-specific optimisation.

In this service, ALUCOBOND® designs and optimises complete solar shading solutions for each project. The process begins with detailed sun-path calculations for every facade orientation, ensuring that shading is tailored precisely to local climatic conditions and building geometry. The outcome is a customised shading strategy that provides effective solar protection while maintaining unobstructed outward views.

Based on the solar analysis, ALUCOBOND® provides engineered recommendations on:

- The use of vertical or horizontal fins

- Fixed or adjustable fin configurations depending on performance need

- Fin dimensions, including depth, spacing and projection, to optimise daylight and withstand wind loads

- The right material system for the right application including ALUCOBOND®, ALUCORE® ACCP & Honeycomb or ALUCODUAL®.

- The appropriate fixing mechanism and substructure integration for long-term stability.

This ensures that every shading system designed under the service is both performance-driven and structurally sound.

Integrating Shading Across Building Typologies

From commercial high-rises to institutional and residential architecture, performance-based shading systems are now standard practice. Common applications include:

- Deep horizontal projections on south-facing facades

- Closely spaced vertical fins for west facades

- Perforated aluminium screens for diffused light control

- Lightweight honeycomb fins for large-span shading elements

- Parametric shading arrays informed by climatic modelling

These approaches enhance the performance and design quality of modern exterior facade design ideas while meeting increasingly ambitious environmental benchmarks.

Conclusion

Sustainable facade design is built on the synthesis of shading geometry, building orientation and envelope performance. As the architectural community seeks to reduce operational energy consumption, solar shading stands out as the most data-driven design strategy.

The ALUCOBOND® Solar Shading Software Service strengthens this approach by providing precise analytical support by enabling architects and facade engineers to create shading systems that balance efficiency, durability and architectural clarity.

With high-performance materials such as ALUCOBOND®, ALUCORE® ACCP & Honeycomb and ALUCODUAL®, alongside a range of advanced finishes, designers can deliver facades that meet both technical performance criteria and the evolving visual language of contemporary architecture.

Ready to elevate your next project? Explore, design and build with confidence.

Discover the full range of ALUCOBOND® solutions and unlock design freedom backed by proven performance.

Connect with our team at info@alucobond.com.sg for specifications, samples and technical support.