Fire safety in modern architecture extends beyond compliance. It’s about ensuring occupant protection, asset preservation and long-term resilience. Aluminium Composite Panels (ACP), commonly used for facades and interior applications, vary significantly in their fire performance. The most important indicator of this performance is their fire resistance rating of materials, typically defined under the EN 13501-1 standard.

Understanding these ratings, particularly Class A fire rating, Class A2 fire rating and Class B fire rating is vital when specifying ACP panels for projects where safety and design must coexist. This guide explains these classifications, their practical implications and how ALUCOBOND® A2 and ALUCOBOND® PLUS lead the way in tested and certified fire rated materials.

1. Why Fire Rating Matters in ACP Panels

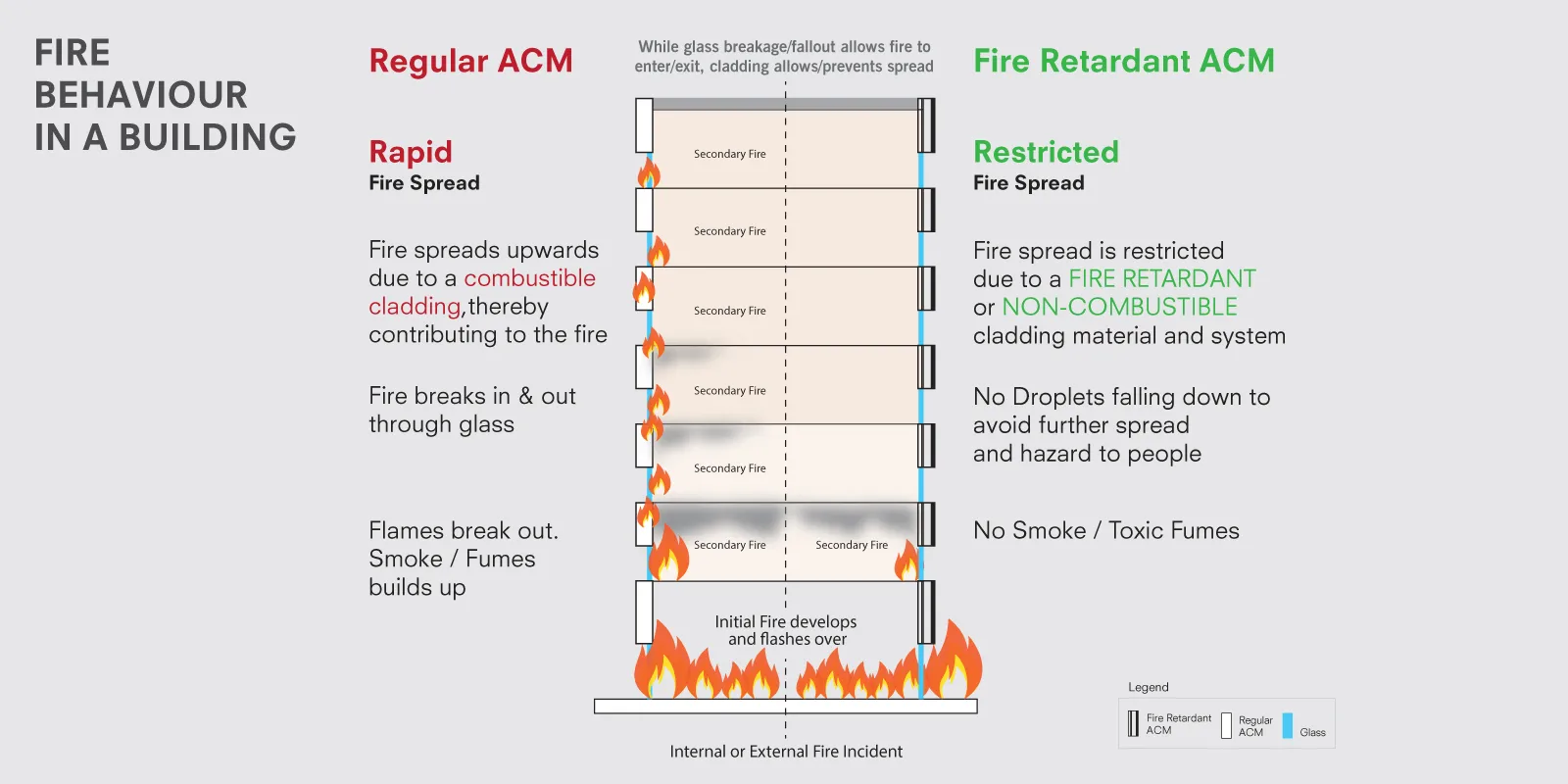

The facade is the first line of defense against fire propagation. In the event of a blaze, cladding materials can either slow down the spread or contribute to it. As outlined in EN 13501-1, every building material is tested for:

- Flame spread behaviour

- Smoke emission (s1, s2, s3 classification)

- Burning droplets (d0, d1, d2 classification)

Only materials that effectively self-extinguish, emit low smoke and prevent flaming droplets are classified as fire resistant materials.

The choice between a fire-rated ACP and a non-fire-rated ACP directly impacts evacuation time, structural integrity and overall building safety, particularly in high-traffic zones such as airports, hospitals, schools and high-rise buildings.

2. Understanding EN 13501-1 Fire Classification

The European Standard EN 13501-1 is the benchmark for assessing the reaction to fire of construction products. It classifies materials based on their contribution to fire growth and spread.

| Fire Rating | Combustibility | Smoke Emission | Droplet Formation | Typical Application |

|---|---|---|---|---|

| Class A1 | Completely non-combustible | Negligible smoke | No flaming droplets | Aluminium, steel, concrete, mineral wool |

| Class A2 | Limited combustibility (non-combustible core) | s1 – minimal smoke | d0 – no droplets | ALUCOBOND® A2 facade panels |

| Class B | Low combustibility | s1 – limited smoke | d0 – no droplets | ALUCOBOND® PLUS facades and interiors |

3. The Difference Between Fire Rating and Fire Retardancy

While all materials may have a fire resistance rating, not all are actually fire retardant.

- Fire rating defines how a product reacts to fire.

- Fire retardancy defines how effectively it prevents or slows the fire from spreading.

A true fire retardant ACP must contain at least 70% non-combustible mineral content in the core, comply with global standards (such as EN 13501-1, NFPA 285, BS 8414) and be installed using recommended fixing systems. Third-party certifications, such as those from TÜV SÜD, further ensure long-term compliance and manufacturing quality.

4. EN 13501-1 Explained: Class A1, A2, and B

Class A1 – Non-Combustible Materials

Class A1 is the highest level of fire resistance, reserved for materials that do not contribute to fire under any circumstances. They emit almost no smoke and produce no flaming droplets. Typical examples include mineral wool, concrete, stone, and solid aluminium sheets such as ALUCOLUX®, which achieve Class A1 performance without requiring any additional fire retardant treatment.

Class A2 – Limited Combustibility (ALUCOBOND® A2)

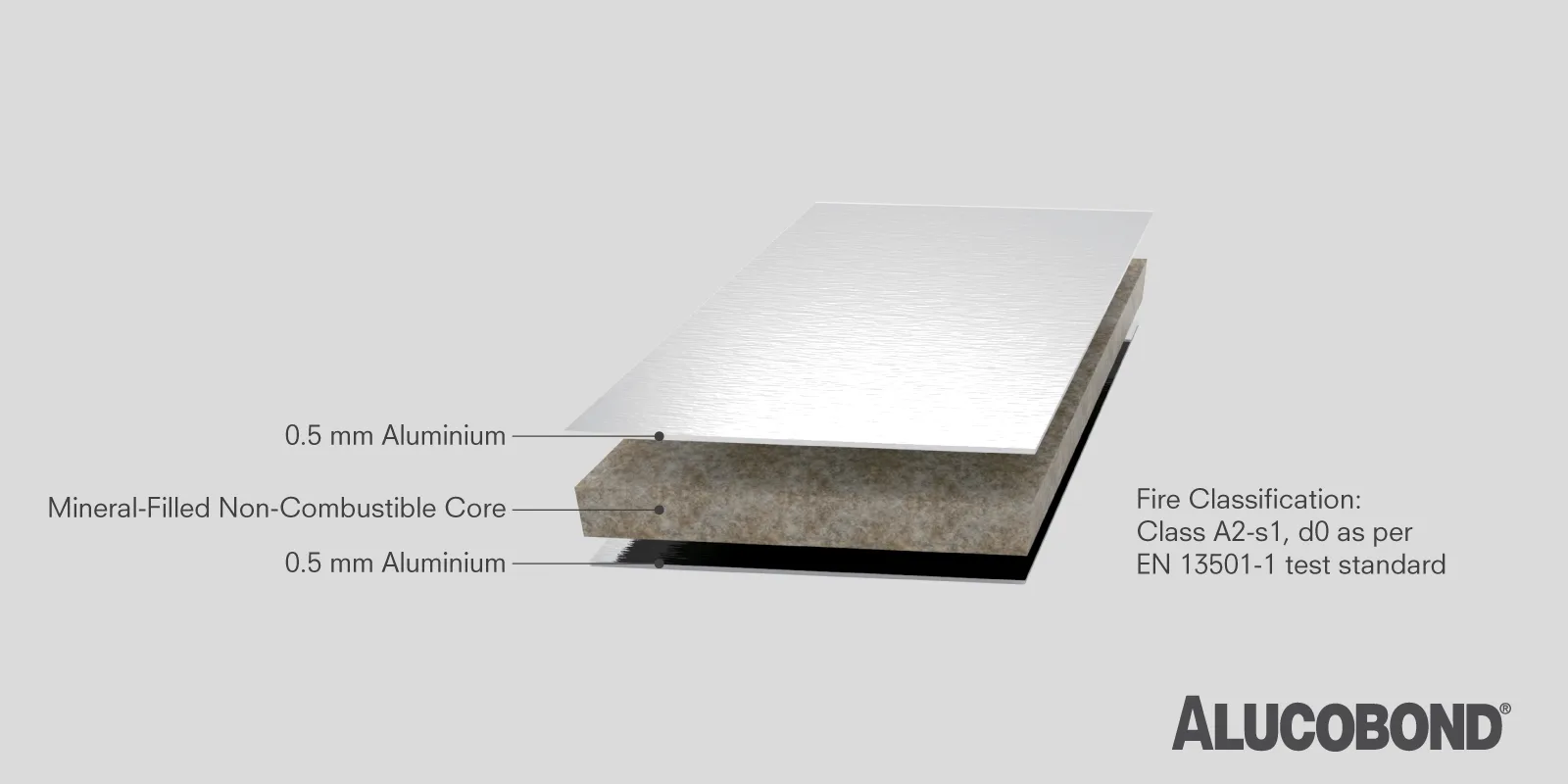

Class A2 fire rating indicates that the material is virtually non-combustible with minimal heat release. It is the maximum fire rating achievable for Aluminium Composite Panels till date.

ALUCOBOND® A2 achieves EN 13501-1 Class A2-s1, d0, ensuring:

- Negligible smoke emission (s1)

- No flaming droplets (d0)

- A non-combustible mineral compound core that prevents flame spread

It also meets additional standards such as BS 6853 and NFPA 285, making it ideal for airports, hospitals, high-rises and public infrastructure projects.

Class B – Fire Retardant (ALUCOBOND® PLUS)

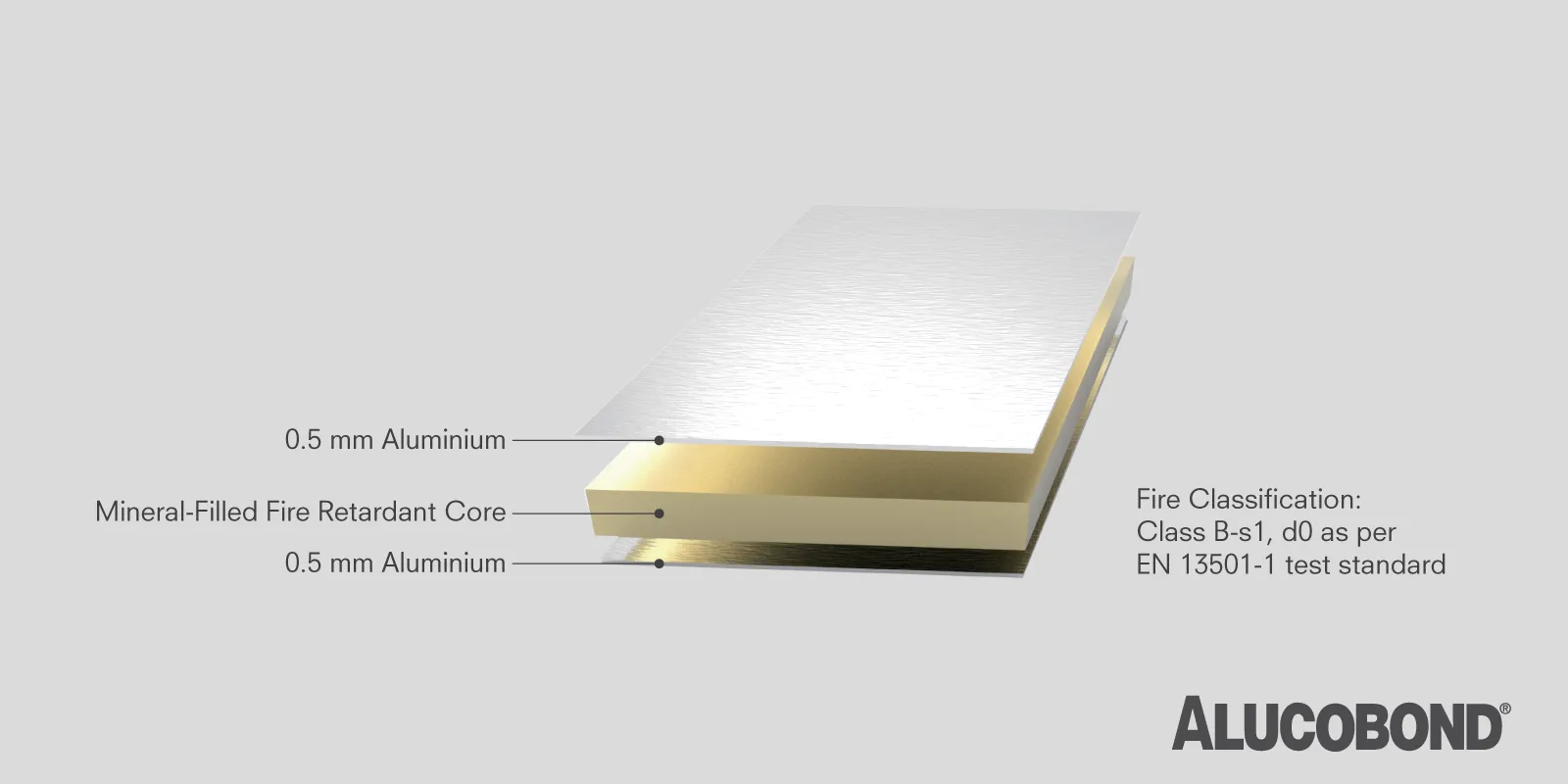

Class B fire rating materials offer strong resistance to ignition and restricted flame spread, suitable for most medium-rise and commercial applications.

ALUCOBOND® PLUS, tested as Class B-s1, d0, provides:

- Mineral-filled fire retardant core

- Hardly inflammable composition

- No flaming droplets and low smoke emission

It has been approved for outdoor wall cladding of any building type without height limitations in Europe, US and Asia.

5. Comparative Summary: ALUCOBOND® A2 vs ALUCOBOND® PLUS

| Parameter | ALUCOBOND® A2 | ALUCOBOND® PLUS |

|---|---|---|

| EN 13501-1 Classification | Class A2-s1, d0 | Class B-s1, d0 |

| Core Composition | 90% mineral core | 70% mineral core |

| Combustibility | Non-combustible | Fire retardant |

| Smoke & Droplets | Minimal smoke, no droplets | Minimal smoke, no droplets |

| Global Compliance | NFPA 285, BS 6853, AS ISO 9705 | ASTM E84, BS 476, NFPA 285 |

| Best Used For | High-rise, hospitals, transit hubs | Commercial, retail, medium-rise |

6. Choosing the Right Fire-Rated Material

When recommending facade, ACP system should meet both product and system-level fire tests:

- EN 13501-1 for product reaction to fire

- BS 8414 or NFPA 285 for facade system behaviour under real fire conditions.

A true fire retardant solution combines:

- Verified test certifications

- Recommended installation system

- Third-party audit of manufacturing and QA processes

All ALUCOBOND® products are Class 1A certified by TÜV SÜD or has Thomas Bell-Wright’s certification, meaning not only the panels but also production processes undergo periodic audits for compliance.

7. Global Compliance and Design Flexibility

Beyond safety, ALUCOBOND® panels retain hallmark design advantages like smooth surface, flatness, formability, weather resistance and a wide range of colours and finishes. This makes it possible to achieve architectural creativity without compromising safety standards.

Whether for airports in Singapore, high-rise facades in Europe or transit terminals in Middle East, ALUCOBOND® A2 and ALUCOBOND® PLUS continue to set benchmarks in performance, sustainability and aesthetics.

Conclusion

Understanding the distinctions between Class A fire rating, Class A2 fire rating and Class B fire rating is the key to building safer environments.

While Class A1 materials remain entirely non-combustible, Class A2 rated ACPs such as ALUCOBOND® A2 represent the highest achievable fire protection in aluminium composite materials. ALUCOBOND® PLUS, classified as Class B, offers strong fire retardancy for a wide range of architectural applications.

Selecting the right fire rated material ensures not only regulatory compliance but also peace of mind, knowing that your design is as safe as it is salient.

For projects where safety and performance are non-negotiable, choose materials that are tested, certified, and trusted worldwide.

Contact ALUCOBOND® at info@alucobond.com.sg to request certified fire classification data, samples, or technical guidance for your next facade or interior design project.