In contemporary architecture, especially with high-rises, coastal developments or buildings exposed to harsh weather, wind loads are a critical design consideration. Strong gusts, pressure fluctuations and turbulent airflow can place substantial stress on facades and roofs. A material may look good or be easy to install, but if it fails under wind pressure, the consequences can be severe: deformation, detachment, structural fatigue, even safety risks.

This is precisely where aluminium honeycomb panels excel, especially advanced solutions such as ALUCORE®, which are specifically engineered to deliver outstanding wind-load resistance while maintaining their lightweight nature and architectural versatility.

ALUCORE®: Engineered for Wind Load Resistance

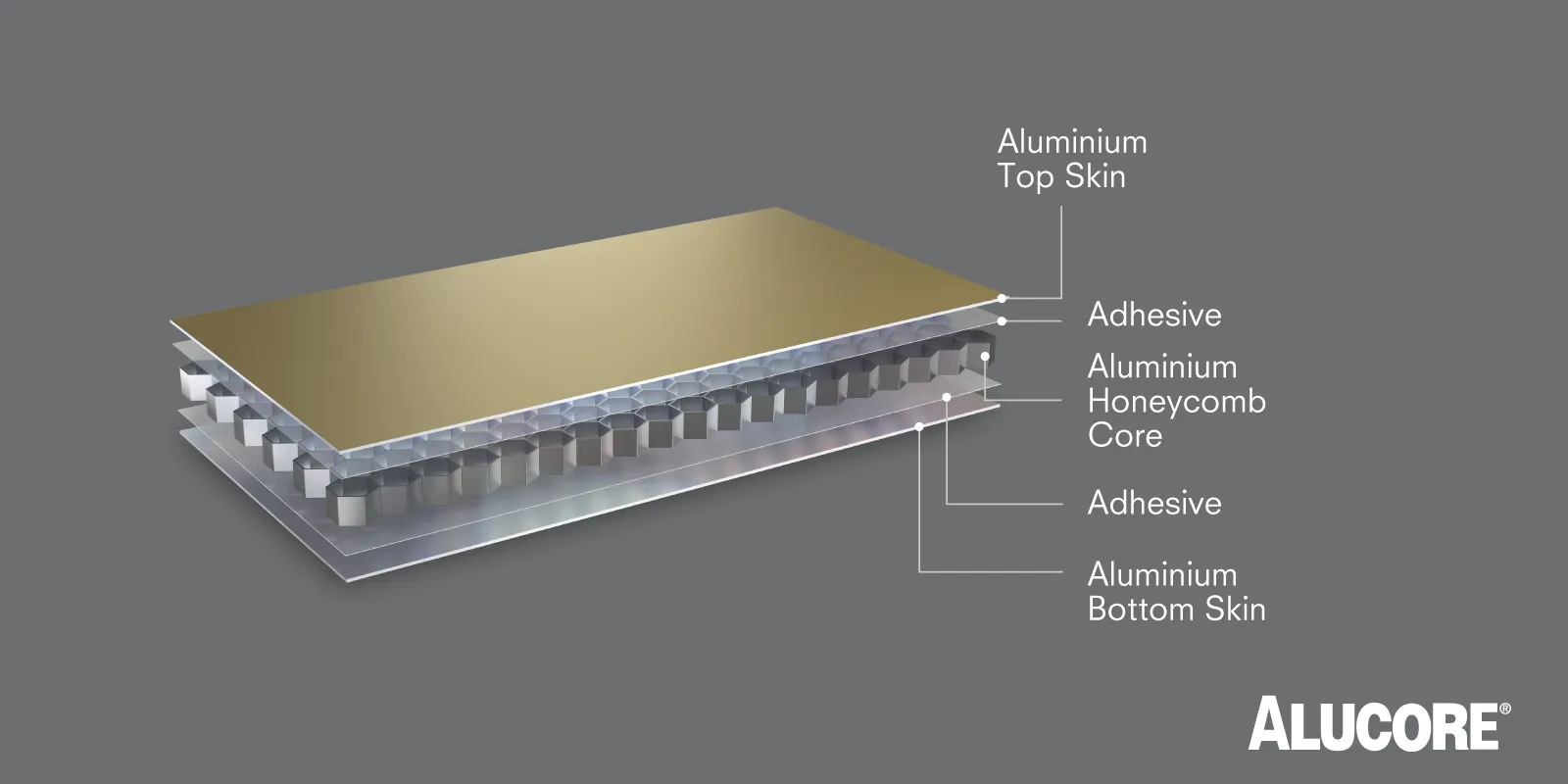

ALUCORE® is an advanced aluminium composite panel that sandwiches a rigid aluminium honeycomb core between two aluminium cover sheets. This sandwich structure provides an outstanding strength-to-weight ratio and makes the panels highly rigid yet light.

Honeycomb panels are recommended for facades or roofing exposed to extremely high wind loads, as well as for large, self-supporting or even walkable roofs for maintenance.

Key design-oriented properties of ALUCORE® that deliver wind resistance:

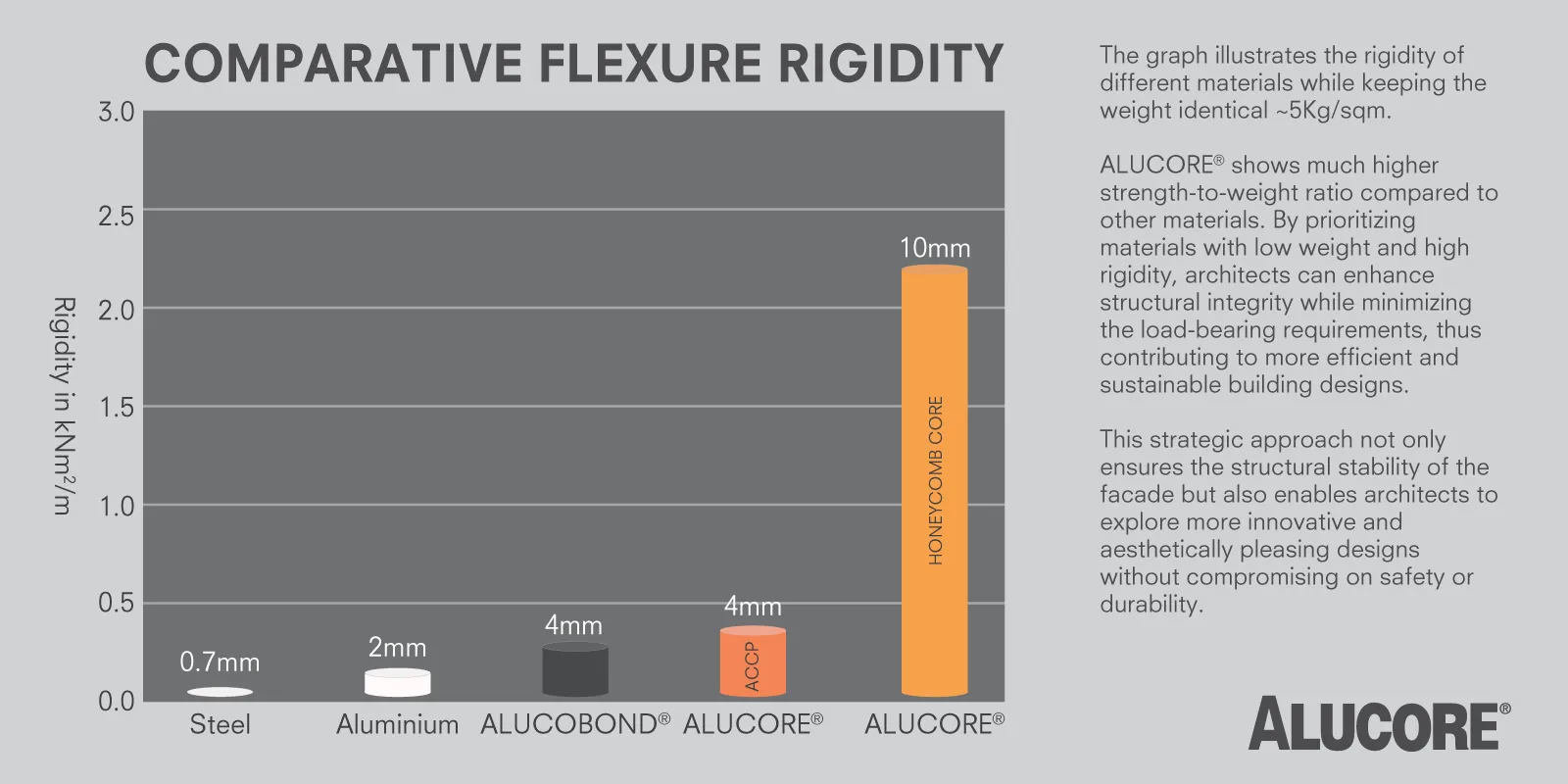

- High flexural rigidity, because the honeycomb core keeps the two skins at a fixed distance, the panel resists bending or deformation under load.

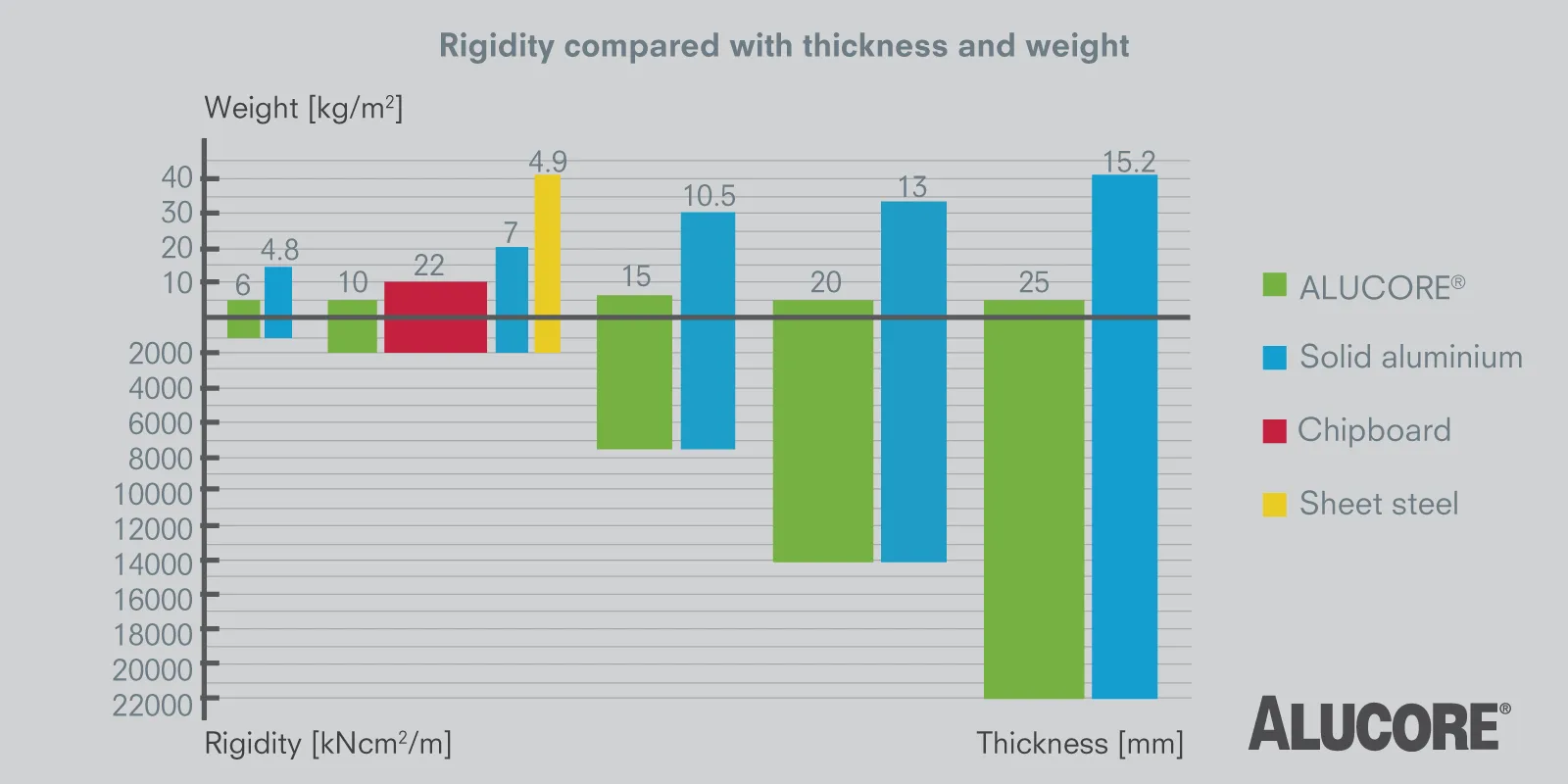

- Exceptional strength-to-weight ratio, the core is mostly air, yet provides a rigid internal framework that distributes stress efficiently.

- Large panel sizes with minimal weight penalty, enabling architects to design expansive facades or roofing spans without excessive structural steelwork, but still retain wind-resistance integrity.

Because of these features, ALUCORE® can tolerate substantial wind pressure that might otherwise warp or damage conventional cladding panels.

Why Honeycomb Structure Excels Under Wind Load?

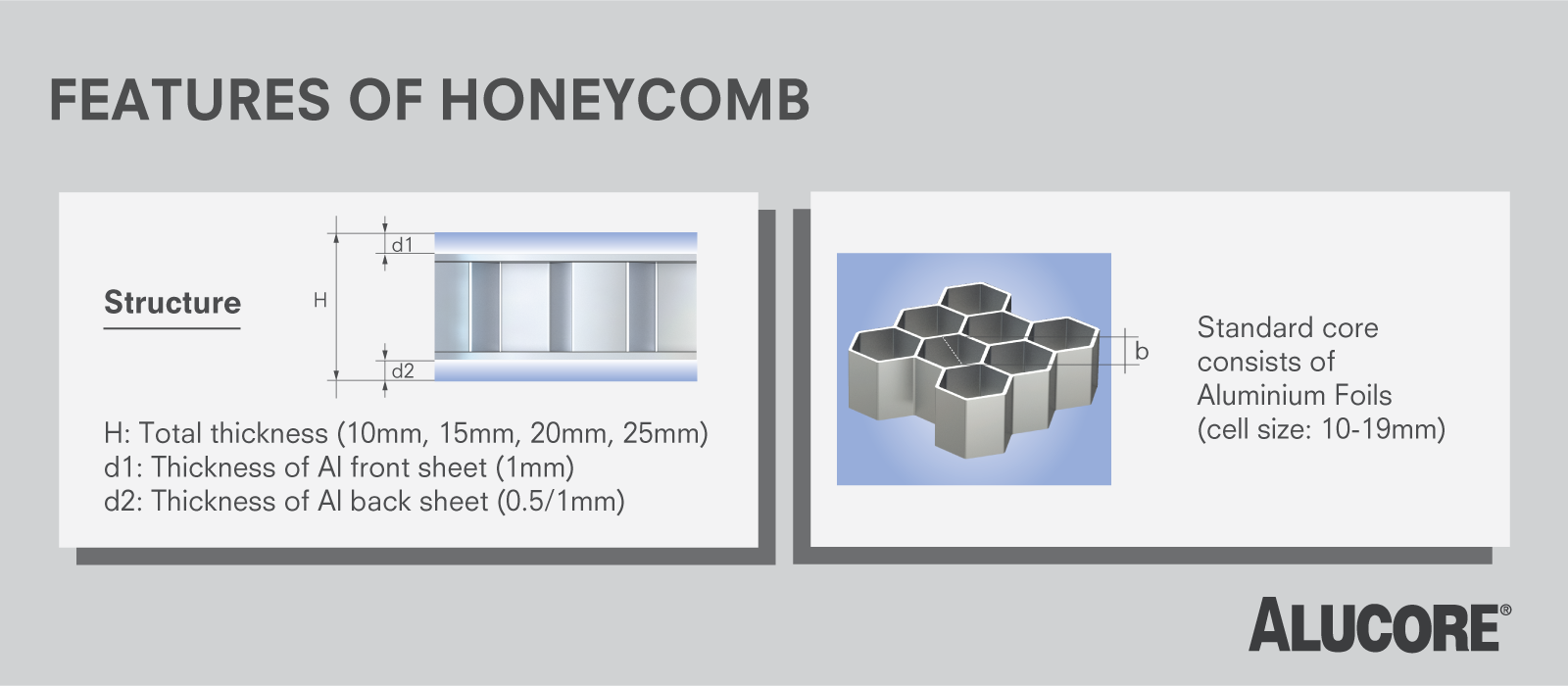

At the heart of wind-load performance is how the panel handles bending, shear and pressure forces. The unique geometry of a honeycomb core with hexagonal cells distributes stress across many small load paths rather than concentrating it, which helps prevent buckling or deformation.

Because of this structure:

- The panel’s skins remain separated by the core, maximising the moment of inertia and greatly improving bending stiffness.

- The load is spread evenly across the panel, reducing stress concentrations that could lead to failure, a key advantage over single-skin or plain composite panels.

- Even large-format panels can maintain flatness under load, which is critically important for facades subject to cyclic wind pressure and suction. Many conventional cladding materials show “oil-canning” (visible ripples or waves) under load; honeycomb panels resist that far better.

In effect, honeycomb systems behave structurally more like a thin, lightweight slab with depth than a mere sheet of metal, and that depth makes all the difference when wind pressure tries to bend or distort the surface.

Real-World Advantages in Envelope Architecture

Using ALUCORE® aluminium honeycomb panels in building envelopes delivers multiple real-world benefits beyond just resistance to wind:

- Safer facades in high-rise and exposed buildings

For towers, coastal developments or buildings in windy climates, the risk of facade deformation or failure is real. ALUCORE® reduces that risk substantially, thanks to its rigidity and strength-to-weight characteristics. - Larger panel spans and clean aesthetics

Architects often wish for large uninterrupted facades for visual impact. With honeycomb panels, it’s possible to use large-span upto 6 meters, thin-yet-rigid panels that don’t sag or deform under wind load helping to achieve smooth, flat surfaces that look premium.

- Lighter overall structural load and cost savings

Because the panels remain lightweight despite high rigidity, supporting structures (sub-frames) can be lighter, simpler and more cost-effective, reducing both initial material cost and long-term load demands.

- Reliable performance under repeated stress

Wind loading is not a one-time event. Facades see repeated cycles of pressure, suction, environmental exposure. The composite honeycomb core ensures dimensional stability, reducing risk of long-term fatigue, warping or loosening.

- Fire Safety

ALUCORE Honeycomb panels® pass the stringent A2-s1, d0 fire classification as per EN 13501-1 test standards, making them safe for occupants as well as the property.

ALUCORE® Beyond Wind: A Full Envelope Solution

While wind-load resistance is a critical advantage, ALUCORE® doesn’t stop there, the panels also deliver excellent flatness, long-term durability, fire safety (no thermoplastic core), corrosion resistance (marine-grade alloy) and a wide variety of finishes, enabling architects to pursue expressive envelope architecture without trading off performance.

In other words, you get wind-resistant facades that look premium, stay stable over decades and perform in all climates, making them ideal for commercial towers, airports, transport hubs, retail complexes, hospitality developments, hospitals and more.

Integrating Honeycomb Panels into wind-sensitive projects

If you plan to use aluminium honeycomb cladding for projects in windy or exposed areas, here are some design principles and best practices to leverage their strengths:

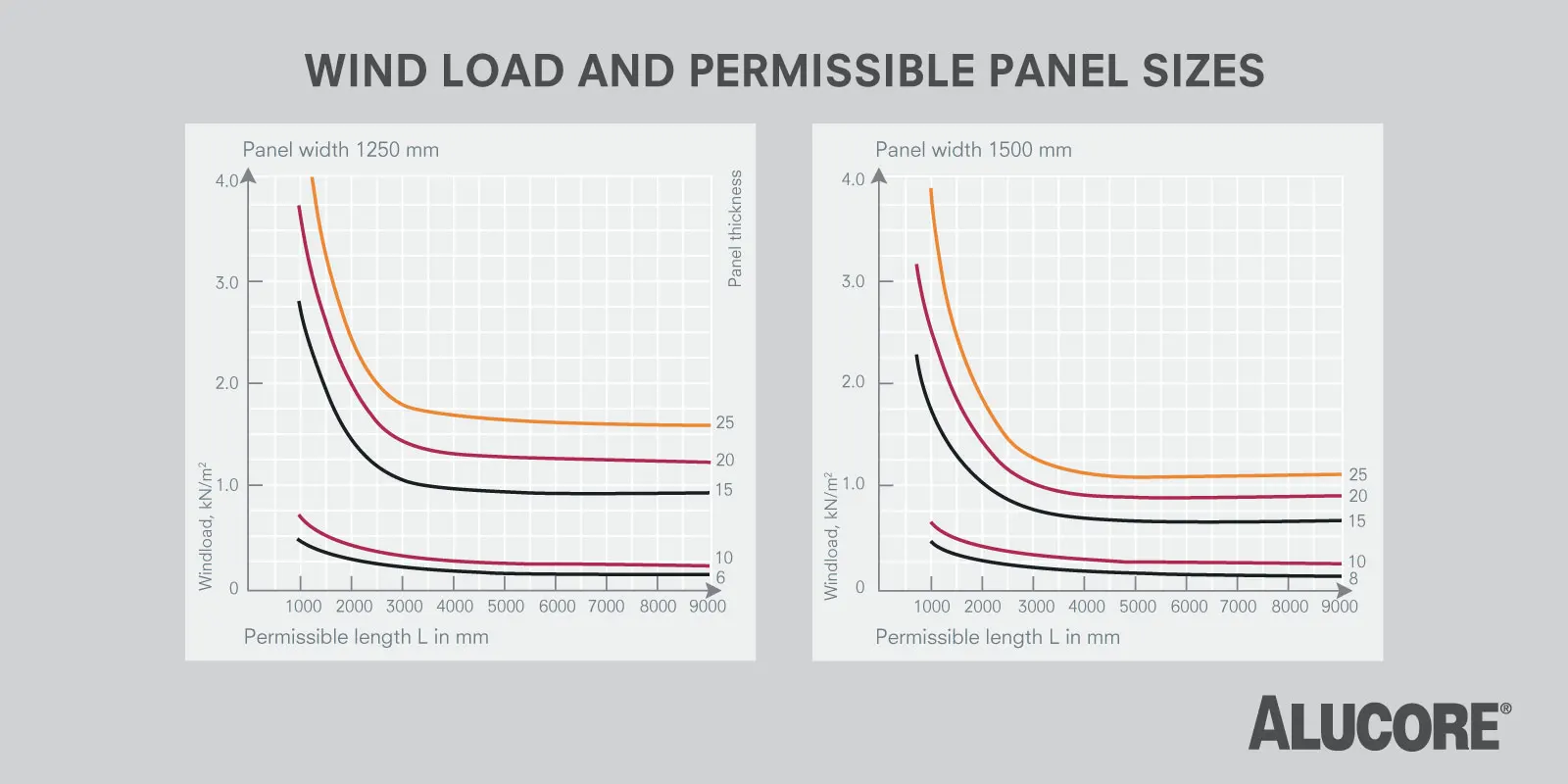

- Use panels of sufficient thickness: ALUCORE® offers 10 mm, 15 mm, 20 mm or 25 mm thickness (or as requested). Thicker panels will naturally offer higher rigidity and better resistance to wind loads.

High strength-to-weight ratio of ALUCORE® aluminium honeycomb panels reduces structural requirements.

High strength-to-weight ratio of ALUCORE® aluminium honeycomb panels reduces structural requirements. - Design for large spans but with proper sub-frame support: While honeycomb panels reduce structural load, correct sub-framing ensures wind forces are distributed safely to the structure.

The diagrams indicate the available range of panel thickness and permissible range lengths at a given panel width (1250 or 1500mm), depending on the loads applied. The diagrams apply to panels supported on four sides (corners fixed). Dimensional values for other systems are available on request.

The diagrams indicate the available range of panel thickness and permissible range lengths at a given panel width (1250 or 1500mm), depending on the loads applied. The diagrams apply to panels supported on four sides (corners fixed). Dimensional values for other systems are available on request. - Select correct coating and alloy: Marine-grade alloy (e.g. ALUCORE® uses 5005 H24) and PVDF/FEVE coating per AAMA 2605 (American Architectural Manufacturers Association) performance specification, ensuring long-term durability even in coastal or industrial climates.

- Consider dynamic loads and facade fixings: Use appropriate anchor systems and allow for natural expansion/contraction under pressure cycles, to avoid fatigue or loosening over time.

- Pair with insulation / thermal & acoustic layers: While structural performance matters, additional layers help envelope architecture meet comfort, energy efficiency and acoustic requirements.

Conclusion

In modern architecture, facades and roofs are no longer just decorative but structural, functional and performance-driven components. As demands for lightweight materials, sustainability and resilience grow, aluminium honeycomb panels, and particularly ALUCORE® emerge as one of the most compelling choices.

They deliver a rare combination: lightweight structure, exceptional rigidity, wind-load resistance, versatility in design and long-term durability. Whether for high-rise towers, coastal buildings, transport hubs or expansive commercial complexes, honeycomb cladding enables architects to craft elegant, safe and future-proof building envelopes without compromise.

Ready to elevate your next project? Explore, design and build with confidence.

Discover the full range of ALUCORE® solutions and unlock design freedom backed by proven performance.

Connect with our team at info@alucobond.com.sg for specifications, samples and technical support.