Architectural facades today serve a deeper purpose than merely enclosing a structure; they articulate identity, intention and innovation. As design philosophies evolve, the demand for facade materials that combine creative freedom, technical performance, long-term durability and environmental responsibility continues to rise. In this landscape, ALUCODUAL®, a premium pre-coated solid aluminium sheet, stands out as a material engineered to meet the complex expectations of modern architecture.

With its exceptional flatness, robust lamination, sophisticated range of finishes, full recyclability and A2 fire rating, ALUCODUAL® aluminium sheet has quickly become a preferred choice among architects who seek a balance of beauty, safety and sustainability. Its ability to deliver expansive, seamless surfaces while maintaining strength and aesthetic consistency positions it as one of the most capable facade materials available today.

The Distinctive Material Integrity of ALUCODUAL®

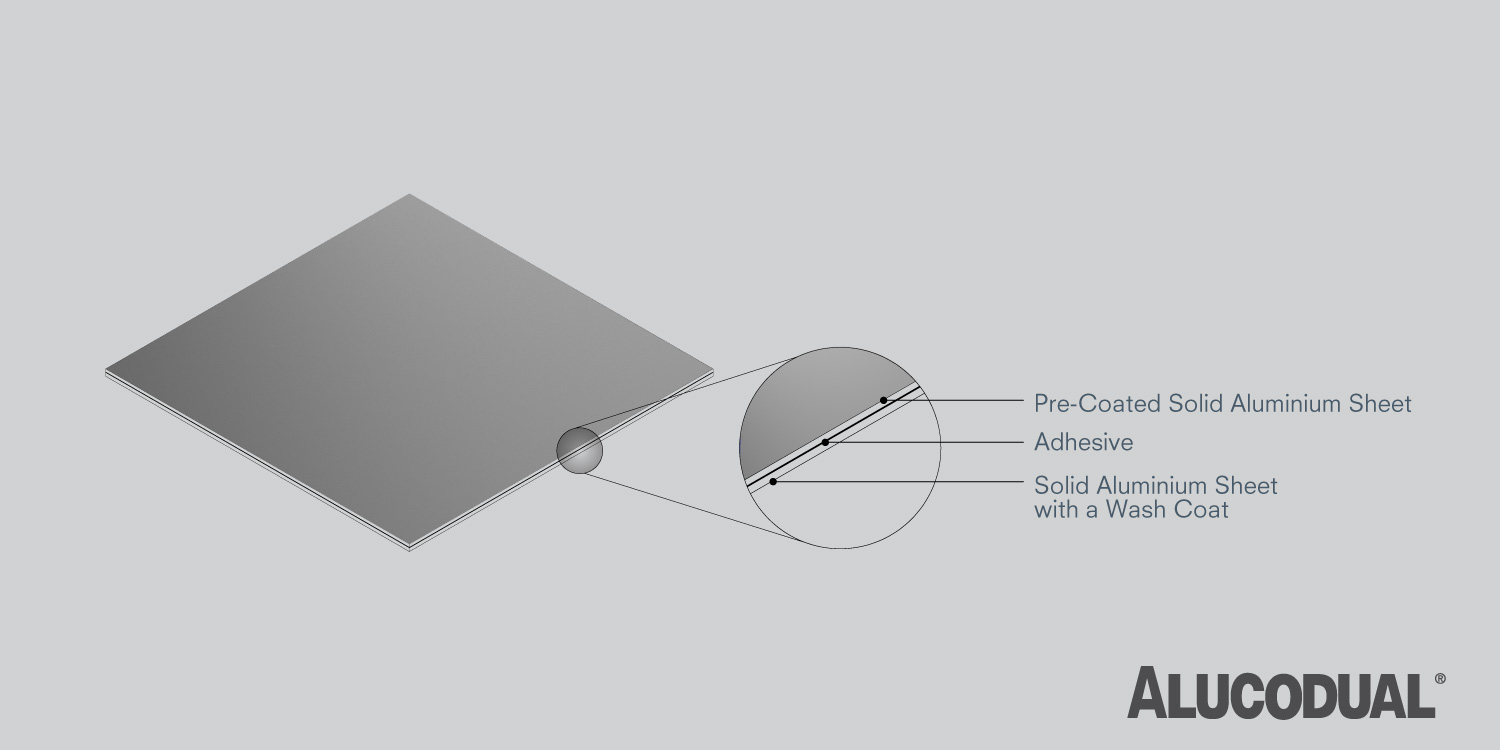

At the core of ALUCODUAL® lies its solid aluminium construction. Unlike hollow or multi-layered panels, ALUCODUAL® is produced as a laminated solid aluminium sheet, giving it remarkable rigidity and an exceptional degree of flatness. This flatness plays a transformative role in architectural facades. When panel surfaces are smooth, tension-free and uniform, the facade reflects light evenly and maintains harmony across the entire elevation. This quality is especially important in contemporary designs where clean, uninterrupted planes are central to the architectural narrative.

ALUCODUAL® is produced using a premium 5xxx-series aluminium alloy in temper H24, a material celebrated for its marine-grade, non-corrosive performance. Enriched with magnesium, this alloy is specifically engineered to withstand harsh environmental conditions, including humidity, salt-laden coastal air and long-term atmospheric exposure, making it an ideal choice for buildings in tropical and marine climates. The H24 temper, achieved through controlled cold working followed by partial annealing, ensures excellent strength, remarkable flatness and stable mechanical properties across the sheet. This combination of marine-grade corrosion resistance, structural rigidity and dimensional stability provides architects and facade engineers with a material they can trust for enduring, large-format facade applications. When paired with ALUCODUAL®’s advanced PVDF/FEVE coil-coated finish, the result is a solution suited for long-term durability, colour retention and performance across Singapore and the wider Asia-Pacific region.

Larger Panels, Fewer Joints and Greater Design Freedom

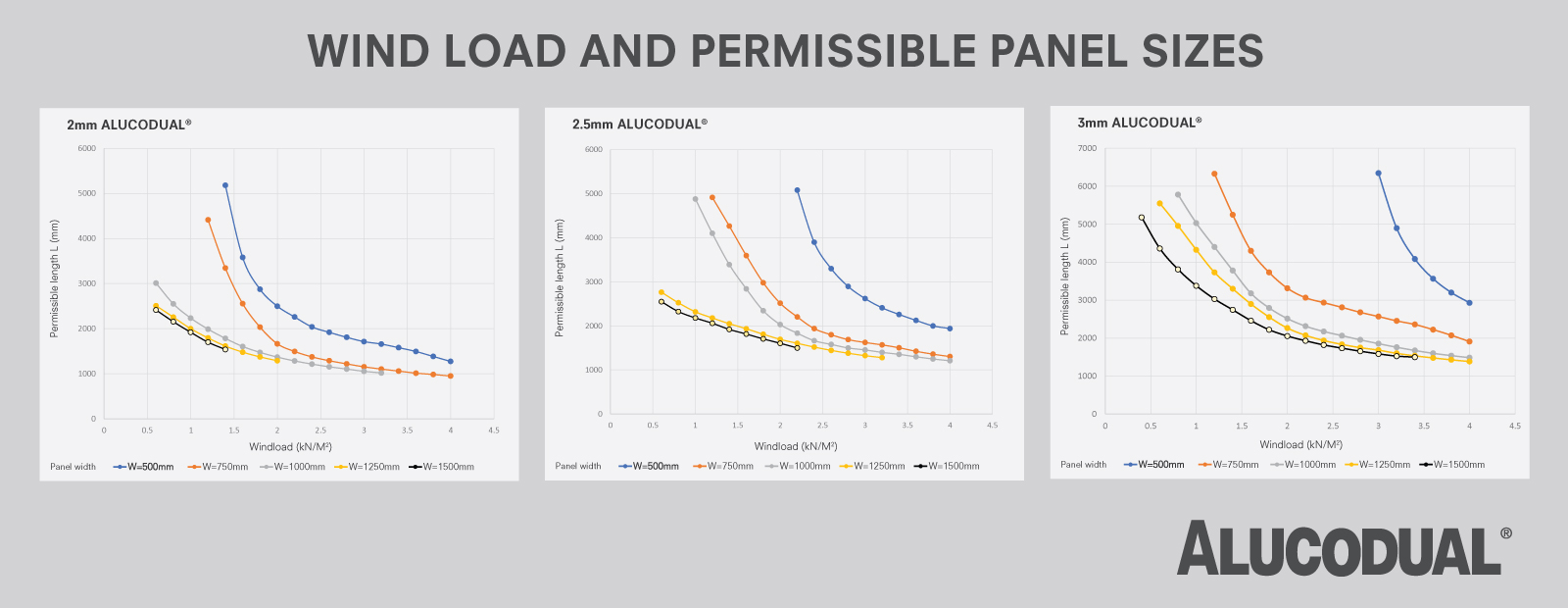

One of the most celebrated attributes of ALUCODUAL® is its ability to support significantly larger panel sizes than other traditional facade materials. These large-format sheets allow architects to minimise the number of joints across the facade, resulting in visually clean surfaces that emphasise elegance and modernity. Fewer joints do not simply contribute to aesthetics; they also streamline fabrication, reduce installation time and decrease long-term maintenance; all essential benefits for builders and developers.

This capacity for large panels unlocks substantial creative potential. Whether used for sweeping vertical facades, long horizontal ribbons or fluid three-dimensional forms, ALUCODUAL® aluminium sheet accommodates sophisticated design expressions without warping or distortion. The material’s structural integrity ensures that even bold, expansive concepts can be executed with confidence.

Pre-Coated Excellence: The Superiority of Coil-Coated Finishes

Architectural facades rely majorly on the quality and durability of their surface finish. ALUCODUAL® distinguishes itself with its advanced PVDF/FEVE Coil Coated finish, applied through a continuous industrial process that ensures exceptional consistency and performance.

Coil coating is one of the most reliable methods for delivering a flawless and long-lasting finish. Each painted aluminium sheet undergoes rigorous cleaning, pretreatment, priming and multi-layer coating in a controlled environment. This uniform process results in:

- Superior resistance to UV exposure

- Long-term colour retention

- Excellent protection against humidity and corrosive conditions

- Consistent appearance across all panels

Unlike post-coated surfaces, coil-coated finishes do not suffer from variations in texture, gloss, or colour, ensuring that even on large facades, every panel exhibits the same depth and vibrancy. In tropical climates, where high humidity, intense sun and coastal environmental factors can accelerate surface degradation, this consistency becomes a major advantage.

Design Versatility Through Colours, Textures and Finishes

One of the defining aspects of contemporary architecture is the desire for visually distinct buildings that express individuality and cultural relevance. To meet this demand, ALUCODUAL® is available in an extraordinary range of colours, textures and finishes. From sophisticated metallics and subtle matte tones to glossy finish aluminium sheets and natural material-inspired designs, the palette is extensive and versatile.

Architects can choose from solid colours, anodised-look surfaces, stone textures or wood patterns depending on the design context. This variety enables the material to be used not only for exterior facades but also for internal feature walls, soffits, ceilings and sculptural elements. With 3A Composites’ colour-customisation service, designers can go even further by developing bespoke shades tailored to specific brand requirements, thematic concepts or heritage-inspired palettes.

Such diversity ensures that ALUCODUAL® aluminium cladding sheet can adapt effortlessly to projects ranging from commercial towers and residential developments to civic structures and cultural landmarks.

Fire Performance That Inspires Confidence

In today’s architectural and regulatory environment, fire safety is non-negotiable. ALUCODUAL® is engineered as a non-combustible material with an A2-s1, d0 classification as per EN 13501-1 test standards, ensuring that it does not contribute to fire spread and maintains stable performance under high temperatures. This classification makes ALUCODUAL® suitable for high-rise structures, public buildings, transportation hubs and other environments where strict fire compliance is essential.

The peace of mind provided by its fire performance is invaluable for architects and developers who must prioritise occupant safety while maintaining design intent. The fact that this high level of safety is achieved without compromising on design or finish quality underscores the technical excellence of ALUCODUAL® aluminium sheet.

Sustainability at the Heart of Modern Construction

As global priorities shift toward more environmentally conscious construction practices, facade materials must demonstrate responsible sourcing, recyclability and long service life. Aluminium is one of the few materials that can be recycled indefinitely without losing quality. At the end of a building’s lifecycle, these sheets can be reprocessed into new aluminium products with minimal environmental impact.

Beyond recyclability, ALUCODUAL® contributes to sustainability through its durability. Its coil-coated surface resists fading, corrosion and weathering, reducing the need for replacement. This long-term performance lowers the carbon footprint associated with renovation and maintenance, aligning the material with efficient and sustainable lifecycles.

3A Composites further enhances resource efficiency through its panel optimisation service, which minimises material waste during facade fabrication. This service helps project teams reduce offcuts, optimise panel layouts and ensure that the material is used with precision and responsibility.

Versatile Applications for Interior and Exterior Architecture

Although known primarily as a facade material, ALUCODUAL® excels across a wide range of architectural applications. Its perfect flatness, lightweight nature and extensive aesthetic possibilities make it suitable for interior walls, ceilings, column cladding, canopy undersides and artistic installations. Architects who pursue visual continuity between indoor and outdoor spaces find ALUCODUAL® aluminium sheet valuable, as its finishes allow seamless transitions across building zones.

In high-traffic interior environments such as airports, stadiums, hospitals, malls & multiplexes or universities, durability becomes just as important as appearance. The robust surface of ALUCODUAL®, coupled with its resistance to abrasions and environmental effects ensures that spaces retain their original appeal even under continuous use.

Empowering Architectural Creativity Through Material Freedom

The evolution of facade design has increasingly embraced fluid forms, curved geometries and expressive spatial compositions. Many facade materials struggle to deliver such shapes without visible distortion or structural limitations. ALUCODUAL®, thanks to its laminated structure and lightweight strength, supports the creation of these modern geometries with confidence. Architects can explore bold contours, sculptural profiles and innovative building skins while retaining the material’s surface integrity.

This design freedom is essential in a world where architecture is expected to inspire, elevate public spaces and create iconic identities. ALUCODUAL® aluminium cladding sheet becomes a medium through which artistic imagination translates into built form.

Conclusion: The Benchmark for Modern, Sustainable and Safe Facades

The architectural world continues to push boundaries, seeking materials that can keep pace with progressive ideas while meeting stringent performance expectations. ALUCODUAL® aluminium sheet stands at the forefront of this evolution. With its flawless flatness, superior coil-coated surfaces, large panel capabilities, sustainability credentials, A2 fire rating and unparalleled design versatility, it captures everything modern facades should represent.

It offers the strength of engineered material performance, the beauty of limitless aesthetic possibilities and the assurance of long-term reliability. For architects who wish to create structures that are expressive, responsibly built and resilient for decades, ALUCODUAL® is the ideal choice.

Ready to elevate your next project? Explore, design and build with confidence.

Discover the full range of ALUCODUAL® solutions and unlock design freedom backed by proven performance.

Connect with our team at info@alucobond.com.sg for specifications, samples and technical support.