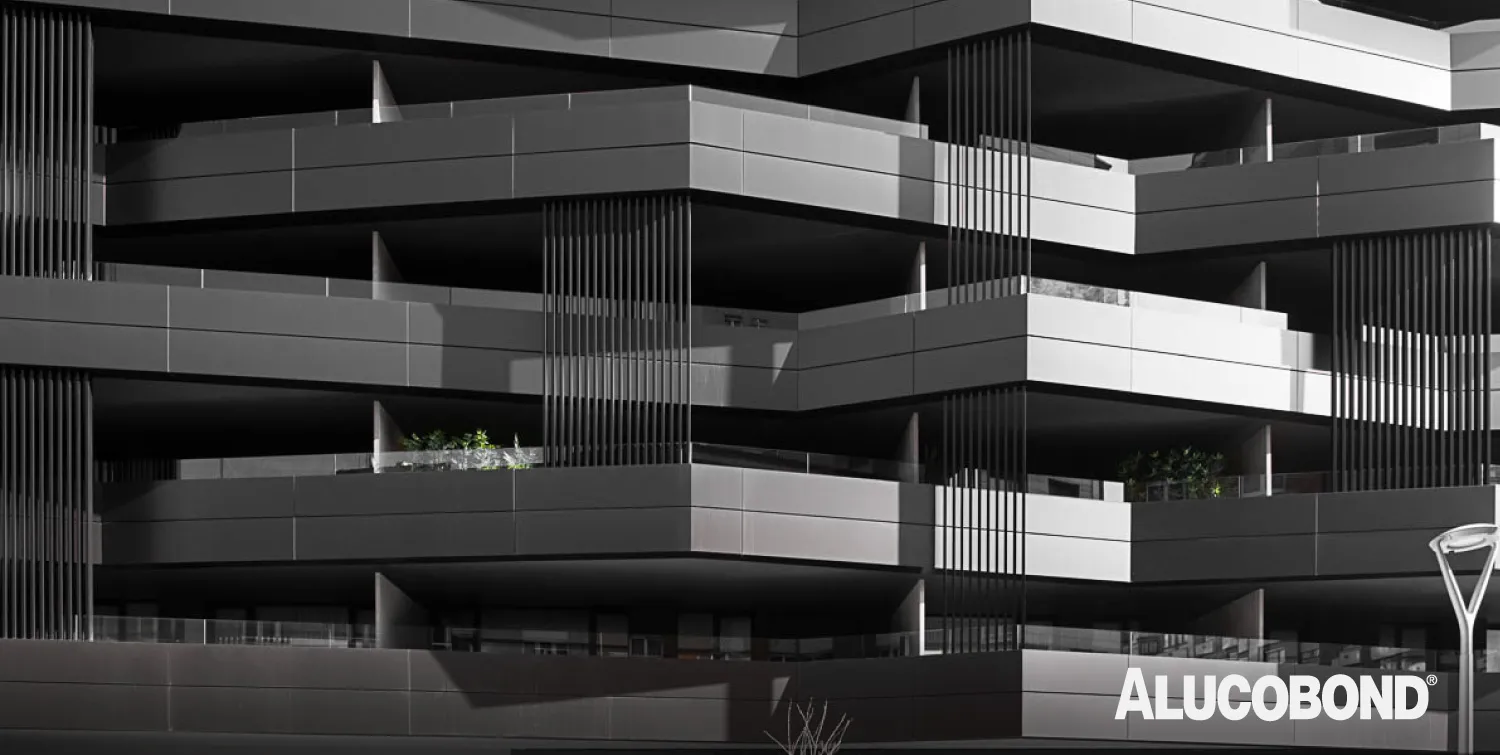

The refined, metallic sheen of anodized aluminium has been a favourite since long for facades, interiors and signage. Today, designers demand the look of real anodizing but with improved long-term performance, consistent colour options and a broader colour palette. Enter ALUCOBOND®’s Anodized Look series. A PVDF-finished aluminium composite solution, engineered to deliver the aesthetic depth of anodized metal combined with the practical advantages of modern coatings. In this guide we explore surface and colour trends, why to choose an anodized-look PVDF finish over actual anodizing and the palette options (including black anodized aluminium).

Why the Anodised Look Remains a Designer Favourite

The appeal of anodized aluminium lies in its subtle, satin-metallic surface that complements many architectural styles ranging from minimalist and industrial to premium corporate designs. Current trends show designers favouring:

- Warm metallics (brass, champagne, bronze) to add sophistication to hospitality and retail facades.

- Cooler greys and titanium tones for corporate and public buildings seeking understated elegance.

- Deep, dramatic finishes such as black anodized aluminium for high-contrast framing, canopies and louvers.

Today, it’s not just about how a surface looks but how well it performs over time. Architects and designers expect finishes that won’t fade, chalk or lose their uniformity after just a few years. That’s why more and more professionals are turning to PVDF-coated aluminium composite panels. They capture the timeless appeal of anodized textures while delivering clear, long-term performance benefits.

Why ALUCOBOND®’s Anodized Look (PVDF) often outperforms real anodizing

Traditional anodizing is an electrochemical process that creates an oxide layer on aluminium giving it an excellent wear resistance, a distinctive metallic finish and good corrosion protection. However, anodizing has limitations:

- Colour range is relatively limited and metallic tones can be difficult to reproduce consistently across batches.

- Anodized surfaces are porous to some degree and can develop surface patina or staining in polluted or coastal environments.

- Achieving uniform appearance on large-panel systems and at joinery edges can be challenging.

ALUCOBOND®’s Anodized Look offers a durable and aesthetically pleasing finish for aluminium composite panels. This finish utilizes a high-performance PVDF (polyvinylidene fluoride) coating system, which is applied through a continuous industrial-grade coil coating line. The process adheres to AAMA 2605 performance specifications for architectural coatings, ensuring superior quality in terms of colour retention, durability and resistance to environmental stressors. This makes it an ideal choice for architectural projects requiring long-lasting and high-quality finishes.

The benefits include:

- Exceptional colour stability: PVDF coatings are formulated to resist fading, even under intense UV exposure. This ensures the anodized aluminium colours stay vibrant and consistent for years to come.

- More shades, more control: A wider palette with precise colour control unlike traditional anodizing, which is limited by the electrochemical process, PVDF finishes open up far more possibilities. From metallic tones to subtle tints, they allow for a broader aluminium composite panel colour range and even custom shades tailored to your project.

- Surface protection and cleaning: PVDF films are easier to clean and resist atmospheric contaminants better than some anodized surfaces, particularly in marine and industrial environments.

- Uniformity across components: PVDF delivers consistent sheen and texture across entire panels and production batches, eliminating patchiness at joints or around cut edges.

For these reasons, specifiers often prefer the Anodized Look series when they want the appearance of anodized aluminium combined with the lifetime performance of modern coil coatings.

Shades and Colour Options

ALUCOBOND®’s Anodized Look collection is typically offered in an array of metallic tones that mimic common anodized effects. Designers can expect options like:

Color Descriptions

Click on the buttons inside the tabbed menu to explore different color options:

A smooth, matte dark brown finish that offers a sophisticated and subtle appearance.

A deep, rich black tone with warm metallic undertones.

A sleek, blackish golden colour with a subtle metallic sheen, exuding modern elegance.

A neutral, anodized look shade with a subtle metallic finish for a contemporary aesthetic.

A medium beige-gold hue with a refined, anodized look for a touch of luxury.

A soft, light gold shade with a gentle metallic gleam for a warm, elegant look.

If you require a detailed aluminium composite panel color chart or specific samples of aluminium composite panel colours, ask your supplier for certified colour swatches and weathering data (accelerated UV tests and salt-spray results). These documents show how a given PVDF anodized-look finish will perform in your climate.

Conclusion

To specify confidently for your next facade or interior project, contact ALUCOBOND® directly for certified samples, detailed performance data, and verified project references. Trusted by architects and designers who used to typically work with anodized aluminium sheet suppliers, are now shifting towards ALUCOBOND®’s PVDF coated panels as they offer a superior alternative over traditional anodizing. Elevate your projects with the perfect blend of aesthetics and durability – choose ALUCOBOND® for unparalleled quality and performance.

Discover the full range of ALUCOBOND® solutions and unlock design freedom backed by proven performance.

Connect with our team at info@alucobond.com.sg for specifications, samples and technical support.