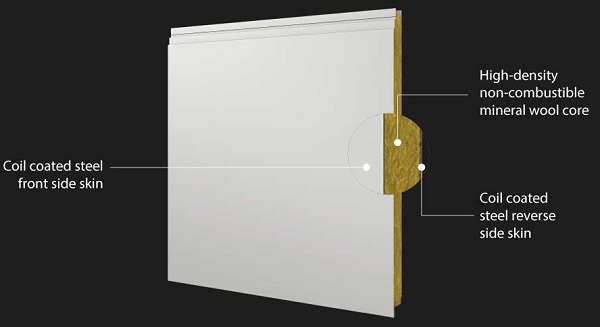

3A Composites’ sandwich panel system is a globally trusted architectural solution that offers excellent insulation, energy efficiency, and fire retardancy. The system is composed of a high-density non-combustible mineral wool core sandwiched between two layers of steel sheets, making it one of the most reliable composite sandwich panels for modern construction needs.

3AC Sandwich Panel System (SPS)

Download our 3AC Sandwich Panel System (SPS) Brochure

![]() PDF [3.31 MB].

PDF [3.31 MB].

Why Choose ALUCOBOND® Sandwich Panels

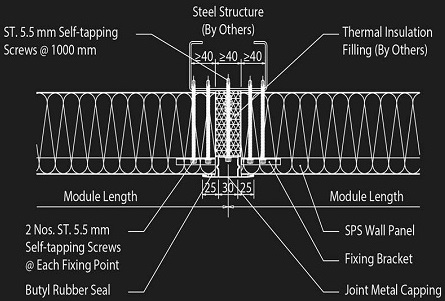

3A Composites’ sandwich panel comes with concealed installation systems that meet the building’s aesthetics, wind load, water tightness, airtightness, insulation, and fire safety requirements. This sandwich panel wall system is used as non-load-bearing walls and partitions for facade and roofing applications.

Apart from offering a variety of sizes, thicknesses, and colour options, the 3A Composites aluminium sandwich panel cladding can also meet various engineering and design requirements. Options for joint types, such as concealed or exposed joints, ensure flexibility for architects and builders.

| Applications | Types of buildings |

|---|---|

| Exterior wall, interior partition, roofing and ceiling. | Data centers, manufacturing facilities, warehouses, cold storages, clean rooms and medical facilities. |

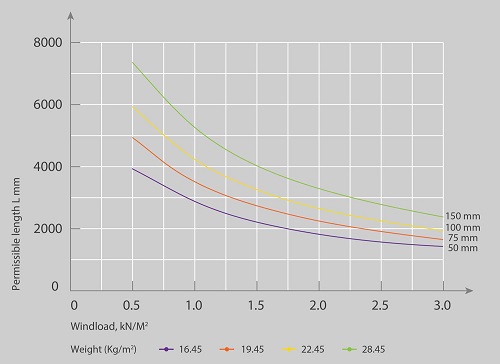

Wind load and permissible panel sizes

The diagram indicates the available range of sandwich panel sizes and permissible lengths at a given panel width, depending on the wind load applied. The diagram applies to panels supported on four sides (corners fixed). Dimensional values for other systems are available on request.

| SANDWITCH WALL PANEL FEATURES |

|---|

![]()

ENERGY SAVING:

With excellent heat insulation performance, 3A Composites Sandwich Panel System can largely reduce heating/cooling expenses and keep the space inside the buildings at desired temperature throughout the year.

![]()

ENVIRONMENTAL PROTECTION:

The system uses natural and environmentally friendly materials that meet the environmental protection requirements in the countries of the European Union and the US.

![]()

SOUND INSULATION AND ABSORPTION:

Due to the use of high-density mineral wool, the 3A Composites Sandwich Panels have good sound absorption performance and also meet the requirements of various construction standards.

![]()

LARGE PANEL SIZE AND EVEN FLATNESS:

The system has a specially constructed composite structure produced on a continuous line that allows for a perfectly flat sandwich panelling surface without the need for reinforcing ribs.

![]()

LIGHTWEIGHT:

3A Composites Sandwich Panel Wall System has high strength and light weight – the weight of a 100 mm panel is about 22 kg/m2, which is much lower than a traditional concrete wall.

![]()

DURABILITY:

The system is designed to withstand harsh conditions and comes with a 10 year warranty*. (*Terms & conditions apply)

![]()

QUICK INSTALLATION:

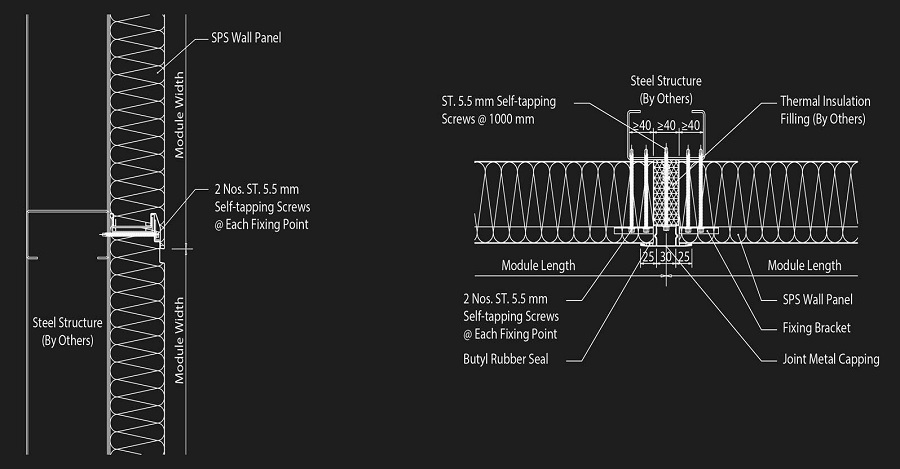

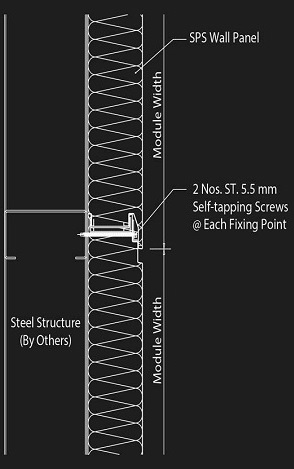

3A Composites Sandwich Panel System can be easily installed by fixing two long sides to meet horizontal or vertical layout requirements. It uses a specially designed dry fastening system which allows for a quick installation.

![]()

TECHNICAL SUPPORT:

3AC technical team provides assistance around product selection, fixing systems and installation methodology.

![]()

FIRE RATING/RETARDANCY:

3A Composites Sandwich Panels have an extremely high fire-resistant mineral wool core.

| Material Properties | ||

|---|---|---|

| Cover Sheet | Flat-smooth/Ribbed, Steel skin on both sides | |

| Cover Material | High density mineral wool | |

| Adhesive | High performance – two component adhesive | |

| Fixing | Hexagon flange head self-tapping and drilling screws with thermal pad | |

| Accessories | Joint metal clip, Weatherproof flashing, End cap | |

| TECHNICAL PROPERTIES | ||

| Panel Thickness | 50 mm | 100 mm |

| Width | 500/600/700/800/900/1000 mm | |

| Length | ≤12,000 mm | |

| Steel Skins Thickness | fs. 0.6 mm / rs. 0.5 mm | fs. 0.7 mm / rs. 0.5 mm |

| Insulation | Mineral wool 120 kg/m³ | |

| Weight (steel) | 15 kg/m² | 22.2 kg/m² |

| Coating | PVDF/ FEVE/ HDP | |

| Accoustic | ≥30 dB | |

| Thermal | U= 0.74 W/(m²K), R= 1.35 (m²K)/W | U= 0.37 W/(m²K), R= 2.7 (m²K)/W |

| Fire Classification | A2-s1, d0 as per EN 13501-1 | |

| Fire Rating | – | 2 hours as per BS 476 part 22 |

*Customise width/length/skin thickness are available upon request.

Frequently Asked Questions about 3A Composites Sandwich Panel System

What is the 3A Composites Sandwich Panel System?

The 3A Composites Sandwich Panel System is a modern architectural solution that combines aesthetics, functionality, and performance. It is designed as a non-load-bearing wall and roofing system, offering insulation, fire safety, energy efficiency, and durability. By using advanced materials and concealed installation systems, these panels meet global standards for building facades and partitions.

What materials are used in the 3AC Sandwich Panel System?

The sandwich panel is made of a high-density non-combustible mineral wool core placed between two layers of durable steel sheets. This combination ensures superior fire retardancy, sound insulation, and thermal performance, making it a reliable and long-lasting building solution.

What makes ALUCOBOND® Sandwich Panels unique compared to traditional walls?

Unlike traditional concrete walls, ALUCOBOND® aluminium sandwich panels are lightweight, highly durable, and energy-efficient. A 100 mm panel weighs only about 22 kg/m², which is significantly lower than concrete. Additionally, they provide excellent insulation, sound absorption, fire resistance, and a perfectly flat surface without the need for reinforcement, making them a smarter and more sustainable alternative.

What applications are 3AC Sandwich Panels suitable for?

The sandwich panel system is versatile and widely used in facades, roofing, partitions, and non-load-bearing walls. Due to its thermal efficiency, fire resistance, and design flexibility, it is suitable for commercial buildings, industrial facilities, warehouses, and modern architectural projects.

How are 3AC Sandwich Panels installed?

The aluminium sandwich panels feature a concealed dry fastening system, making installation quick and efficient. Panels can be installed horizontally or vertically by fixing the long sides, ensuring air-tightness, water-tightness, and a clean, aesthetic finish without visible joints.

What sizes and thicknesses are available?

The sandwich panel system is available in multiple sizes, thicknesses, and colour options to suit different engineering and architectural needs. Large panel sizes with even flatness are produced on a continuous line, ensuring flexibility in design and application.

Can the panels be customized?

Yes, 3AC aluminium sandwich panels can be fully customized in terms of colour, thickness, size, and joint type. Options include concealed or exposed joints, allowing architects and engineers to meet specific project requirements while maintaining design aesthetics.

What are the advantages of ALUCOBOND® Sandwich Panels?

The ALUCOBOND® sandwich panel system offers multiple advantages:

- Energy saving with superior heat insulation

- Environmentally friendly with eco-compliant materials

- Sound insulation and absorption due to high-density mineral wool

- Lightweight yet durable, reducing structural load

- Flat, seamless finish with large panel sizes

- Quick installation using advanced fastening systems

- Fire retardant performance with non-combustible mineral wool core

- Backed by a 10-year warranty* and expert technical support (*Terms & conditions apply)