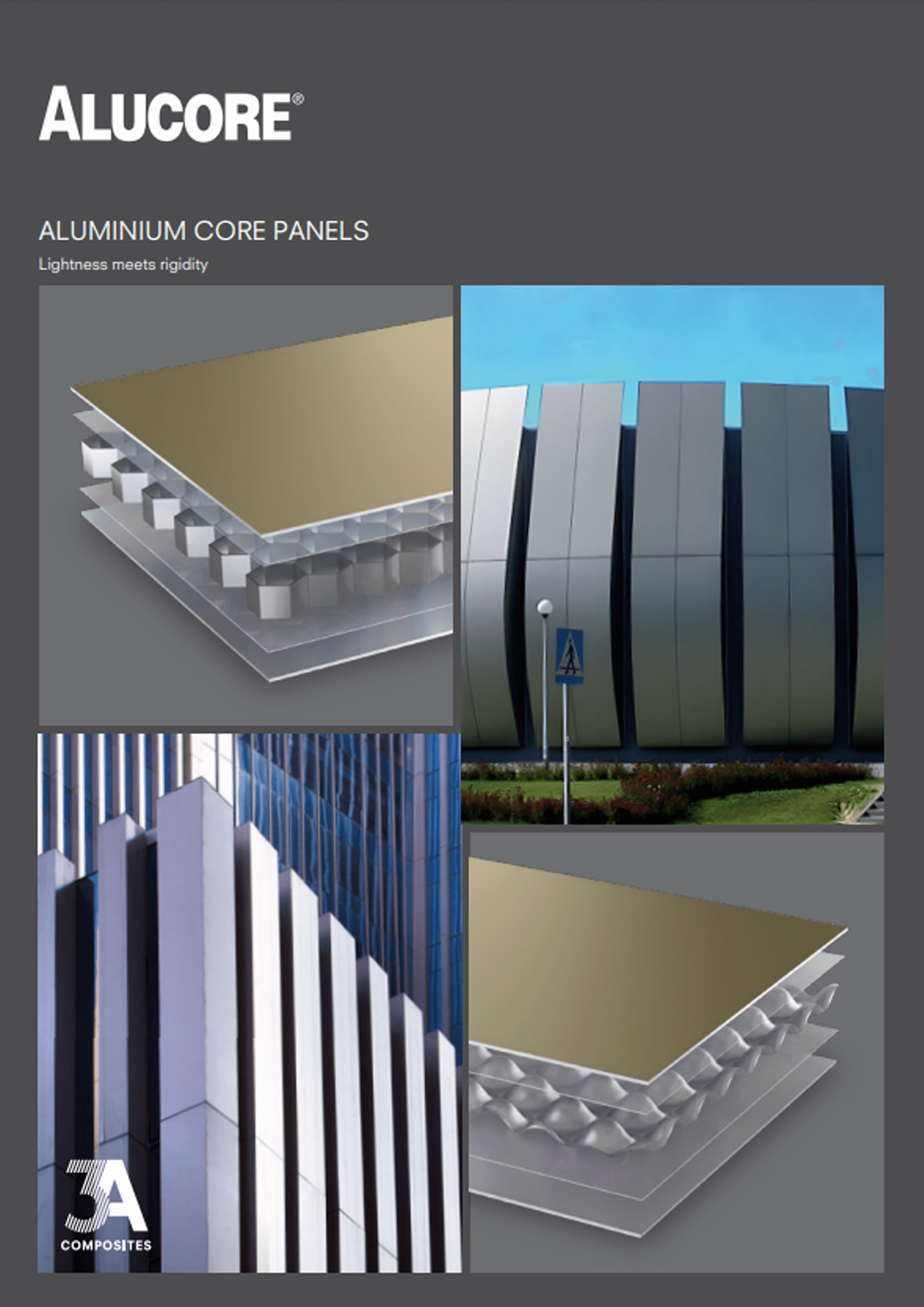

Aluminium Honeycomb & ACCP Panels

ALUCORE® is an innovative aluminium composite panel consisting of two aluminium cover sheets and a core of aluminium.

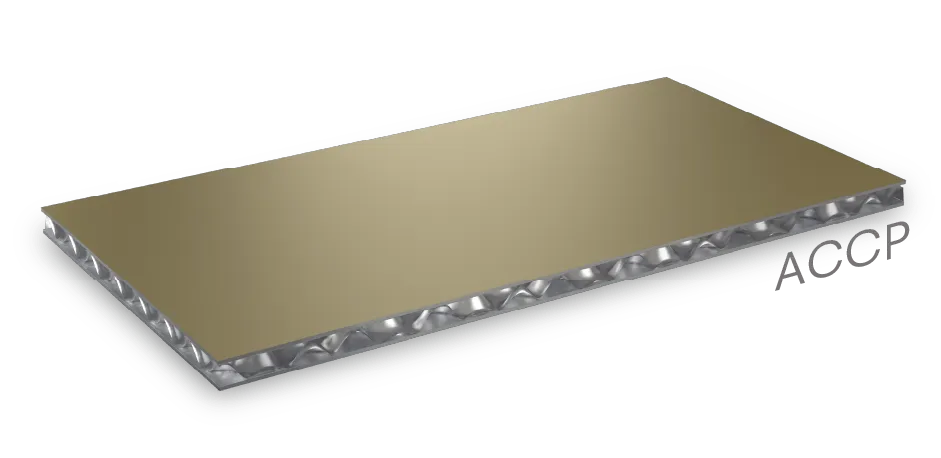

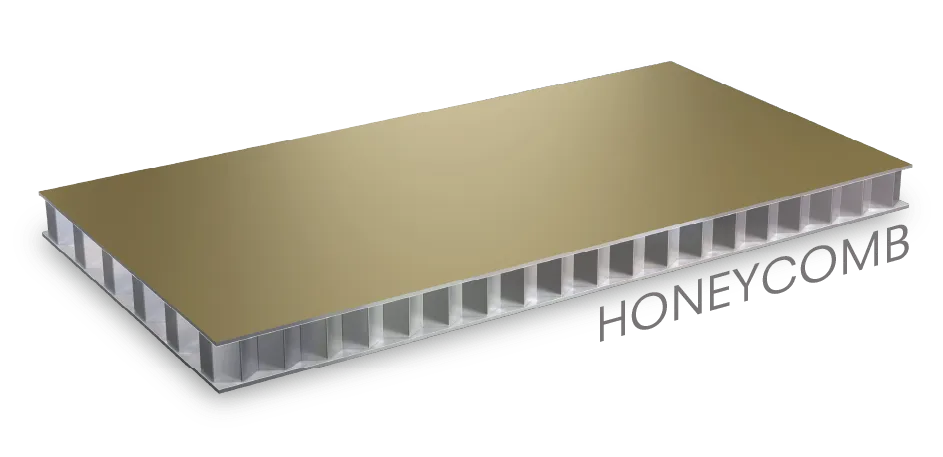

ALUCORE® comes in 2 variants – ALUCORE® ACCP and ALUCORE® Honeycomb panels. ALUCORE® features marine-grade corrosion-resistant alloy 5005 H24 for durability. The PVDF/FEVE coating, as per AAMA 2605, ensures long-term performance and protection from UV radiation and weathering.

ALUCORE® is 100% recyclable, making it an ideal choice for environmentally conscious projects. With a wide selection of colours and finishes, these versatile aluminum core panels can be customized to meet specific aesthetic and functional requirements.

|

Panel thickness (mm) |

Bending radius outside (mm) |

Material gain (mm) |

Folding height min. (mm) |

|---|---|---|---|

| 6 | ~4 | 2.7 | 20 |

| 10 | ~9 | 5.0 | 25 |

| 15 | ~13 | 7.5 | 35 |

| 20 | ~16 | 8.5 | 50 |

| 25 | ~18 | 10.0 | 60 |

Routing and folding technique / producing corners and edges

Important:

These are customised design tools to match the respective machine and can be ordered by the processor from the recommended manufacturers. Please state the tooth geometry, tool diameter etc. The auxiliary tracing rollers can be produced from the existing ALUCORE® tracing rollers for 4mm or 6 mm thickness.

Important:

These are customised design tools to match the respective machine and can be ordered by the processor from the recommended manufacturers. Please state the tooth geometry, tool diameter etc. The auxiliary tracing rollers can be produced from the existing ALUCORE® tracing rollers for 4mm or 6 mm thickness. Frequently Asked Questions about ALUCORE®

What is ALUCORE®?

ALUCORE® is a premium aluminium composite panel that uses an advanced aluminium honeycomb core instead of conventional fillers. These aluminium honeycomb panels are known for their high strength, lightweight structure, and long-term durability. They are ideal for architectural facade, transport, marine, and industrial projects where both performance and aesthetics are crucial.

What makes ALUCORE® different from traditional aluminium composite panels?

Unlike standard ACPs that use polyethene or mineral cores, ALUCORE® incorporates a bonded aluminium honeycomb sheet as its core. This design drastically reduces weight while significantly improving rigidity, impact resistance, and dimensional stability. The result is aluminium honeycomb panels that provide superior durability, fire safety, and structural reliability compared to conventional ACPs.

What are the available variants of ALUCORE®?

ALUCORE® is available in two main variants: ALUCORE® ACCP Panels (for architectural cladding and façade systems) and ALUCORE® Honeycomb Panels. In construction, aluminium honeycomb panels are preferred for facades, roofing, ceilings, canopies, and interior partitions because of their high load-bearing capacity, excellent dimensional stability, fire resistance, and lightweight structure. These properties ensure long-term durability and reduced structural load without compromising on aesthetics.

What is the significance of the marine-grade corrosion-resistant alloy 5005 H24?

ALUCORE® uses marine-grade alloy 5005 H24 in its aluminium honeycomb panels. This alloy provides outstanding corrosion resistance, making the panels highly reliable in humid, coastal, and industrial environments. It prevents rust and degradation while preserving structural integrity and aesthetic finish over the years.

What is the difference between ALUCORE® ACCP and ALUCORE® Honeycomb?

ALUCORE® ACCP Panels are designed for exterior cladding and facade applications, delivering durability and modern aesthetics. On the other hand, ALUCORE® aluminium honeycomb panels are ideal for construction projects that demand lightweight yet highly rigid materials, making them perfect for roofing, canopies, ceilings, and architectural facades where strength and long-term performance are essential.

Where can ALUCORE® panels be used?

ALUCORE® aluminium honeycomb panels are highly versatile. They can be used in architectural facades, roofing systems, canopies, ceilings, and cladding applications. With their strength, lightweight structure, and long-term durability, aluminium honeycomb panels are an ideal choice for modern construction projects requiring both performance and aesthetics.

Is ALUCORE® fire-resistant?

Yes, ALUCORE® is fire resistant because of the aluminium honeycomb core; they do not contain combustible fillers found in traditional ACPs. This makes honeycomb panels compliant with fire safety standards and a safe choice for high-rise buildings, public spaces, and transport projects.

Can ALUCORE® panels be customized in terms of size, colour, and finish?

Absolutely. ALUCORE® aluminium honeycomb panels can be customized to meet specific project needs. Options include tailored sizes, metallic tones, wood or stone finishes, and various surface textures. This flexibility allows architects to achieve the desired performance and look.

Does ALUCORE® meet international quality and safety standards?

Yes. ALUCORE® aluminium honeycomb panels are tested for fire resistance, weather durability, and mechanical strength. They meet globally recognized standards and building codes, ensuring long-term performance and safety trusted by architects and engineers worldwide.

What coating is applied to ALUCORE® for protection?

ALUCORE® panels are protected with high-quality PVDF or FEVE coatings. These finishes enhance resistance against UV rays, weathering, chemicals, and pollution. They also ensure long-term colour stability and a durable surface finish, making aluminium honeycomb sheets look visually appealing for decades.