Prefabricated Aluminium Honeycomb Cladding Panels

ALUCORE® Clad is a Value-Added Cladding System Solution from ALUCOBOND®. It is made of honeycomb panels prefabricated with aluminum extrusions – meaning they are ready to install.

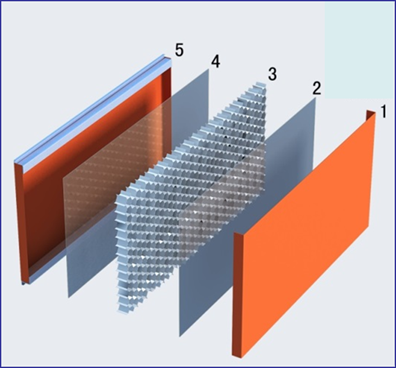

ALUCORE® Clad is comprised of the following:

- The pre-coated Aluminium front skin

- Adhesive

- Aluminum Honeycomb core

- Pre-coated Aluminium back skin and fixing extrusion

Features of ALUCORE® Clad

- Unique, as it combines a custom solution with the best available industrial coating and lamination technology

- ‘Ready to install’ aluminium wall panels which come with different cladding material configurations (finishes/coating/thickness) to suit individual project requirements

- Panel perimeter fixing anchors both panel skins to the supporting structure, thereby giving a better strength to the overall installation

- Pre-fixed extrusions ensure an easy and quick installation, whether horizontal or vertical orientation

- The fixing system used in ALUCORE® Clad allows for quick panel replacement/removal in different structures, rather than having to take out all the panels

ALUCORE® Clad has all the great features of ALUCORE® – combined with a high-quality ‘ready to install’ system for a perfectly designed building.

With ALUCORE® Clad, you get the strength of honeycomb panels combined with the convenience of a high-quality, ready-to-install aluminium wall solution. These aluminium panels for walls are engineered to deliver durability, aesthetics, and functionality in one solution.

Moreover, ALUCORE® Clad meets stringent building safety standards and contributes to compliance with the fire resistance rating of materials, making it a reliable choice for architects and builders looking for safe and sustainable cladding solutions.

With ALUCORE® Clad, your project gets the perfect balance of performance, design, and long-lasting results.

| TECHNICAL ITEM | STANDARD | UNIT | Standard T12mm* | Standard T25mm* |

|---|---|---|---|---|

| SURFACE | ||||

| Front Cover Sheet** | mm | 0.7 ~ 1.0 | ||

| Weight | kg / m2 | 5.5 | 6 | |

| Alloy | EN 573-3 | AA5005A(ALMG1),H42 AA3003, H44 | ||

| Coil Coating System | Coil Coating | PVDF\HDP\POLY | ||

| Gloss (Initial Value) | ECCA T2 | % | 30-45 | |

| Pencil Hardness | ECCA T4 | HB-F | ||

| CORE | ||||

| Cell Size | mm | 6.3 – 19 | ||

| Density | kg / mm3 | > 50 | ||

| Thickness of AI Foil | mm | 0.076 | ||

| Bare Compressive Strength | N / mm2 | ≥ 0.8 | ||

| MECHIANICAL PROPERTIES | ||||

| Modules of Elasticity | EN 1999 1-1 | N / mm2 | 70, 000 | |

| Tensile Strength Cover Sheets | EN 485-2 | N / mm2 | Rm ≥ 125 | |

| 0.2% Proof Stress | EN 485-2 | N / mm2 | Pp0.2 ≥ 80 | |

| Elongation | % | A50 ≥ 3 | ||

| Linear Thermal Expansion | EN 1999 1-1 | 2.4mm/m (at 100℃ temperature Difference) | ||

| ACOUSTICAL PROPERTIES | ||||

| Sound Absorption Factor αs | ISO345 | 0.05 | ||

| Sound Insulation Rw | ISO 717-1 EN ISO 6721 |

dB | 15 | 25 |

| THERMAL PROPERTIES | ||||

| Thermal Conductivity λ*** | DIN 52612 | W/mK | 1.35 | 2.7 |

| Thermal Resistance R | DIN 52612 | m2K/W | 0.0047 | 0.0093 |

| Heat Transition Coefficient U | DIN 4108 | W/m2K | 5.65 | 5.58 |

| Flame spreading in the aluminium surface | BS476, Part 7 | Class 1 | ||

| Surface fire performance | BS1991ADB | Class 0 | ||

Footnotes:

* Based on the specific application, there are kinds of thickness, such as 10mm, 15mm, 20mm, etc.

** There are also 0.5mm or 0.7mm for the front cover sheet according to the specific application

*** Re.to total thickness, incl.al-layers

Frequently Asked Questions about ALUCORE® Clad

What is ALUCORE® Clad?

ALUCORE® Clad is a Value-Added Aluminium Honeycomb Cladding Panel system from ALUCOBOND®. It is made of prefabricated honeycomb panels combined with aluminium extrusions, making it a ready-to-install cladding solution. The system integrates a pre-coated aluminium front skin, honeycomb core, back skin, and fixing extrusion for superior performance.

What are the main features of ALUCORE® Clad?

ALUCORE® Clad offers:

- Unique integration of industrial coating and lamination technology.

- Prefabricated Aluminium Cladding Panels with multiple finishes and thickness options.

- Strong perimeter fixing anchors that enhance durability.

- Pre-fixed extrusions for easy horizontal or vertical installation.

- Quick panel replacement without disturbing the entire structure.

How easy is it to install ALUCORE® Clad panels?

Installation is extremely simple and efficient. Since ALUCORE® Clad is a ready-to-install honeycomb panel system, the prefixed extrusions ensure quick alignment and secure fixing. The system supports both horizontal and vertical orientations, reducing time and labour on-site.

What is the fire resistance rating of ALUCORE® Clad?

ALUCORE® Clad panels are designed with aluminium honeycomb cores and pre-coated skins, which provide enhanced safety and fire-resistant properties.

Is ALUCORE® Clad lightweight compared to traditional cladding?

Yes. Thanks to its aluminium honeycomb core, ALUCORE® Clad is significantly lighter than traditional solid cladding systems. This reduces structural load while maintaining exceptional rigidity and strength.

What advantages does the "ready-to-install" system offer?

The biggest advantage is efficiency. With prefabricated Aluminium Honeycomb Cladding Panels, there is no need for additional fabrication on-site. This saves time, reduces errors, ensures consistent quality, and allows for quick panel replacement if needed.

How does the honeycomb core improve performance?

The aluminium honeycomb core provides an excellent stiffness-to-weight ratio, ensuring the panels remain lightweight yet strong. It also enhances impact resistance, durability, and reduces deflection compared to solid Aluminium Cladding Panels.

Can ALUCORE® Clad be customized?

Yes. ALUCORE® Clad offers flexibility in finishes, coatings, thicknesses, and configurations to match specific architectural and design requirements.

Does ALUCORE® Clad reduce structural load on buildings?

Absolutely. By using lightweight honeycomb panels, ALUCORE® Clad reduces the overall dead load on the building structure without compromising safety or aesthetics.

Does ALUCORE® Clad support ventilated facade systems?

Yes. ALUCORE® Clad is engineered to work seamlessly with ventilated facade systems, enhancing energy efficiency, durability, and modern architectural appeal.