Best FR Aluminium Composite Panels ACP

Whether your project is a private home, a corporate space, a large public building, or an industrial complex, ALUCOBOND® PLUS ACP panels provide durable aluminium cladding solutions with great functionality and creativity. As these composite panels provide great strength with aesthetic appeal, it has become most popular among architects and consultants for facade and other cladding solutions.

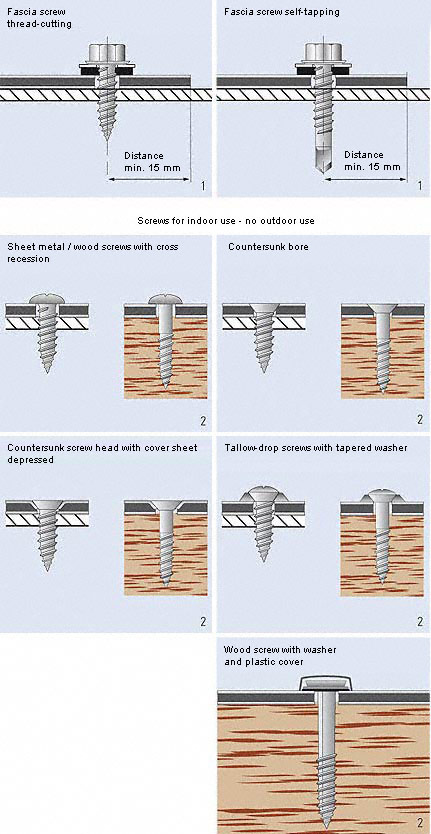

Threaded fasteners for outdoor use

Threaded fasteners for indoor use

Frequently Asked Questions about ALUCOBOND® PLUS

What is ALUCOBOND® PLUS?

ALUCOBOND® PLUS is a premium aluminium composite panel (ACP panel) designed for modern facades and cladding. It features two aluminium sheets bonded to a mineral-filled core, ensuring exceptional durability, enhanced fire safety, and design flexibility. Known for its excellent flatness, weather resistance, and sleek finish, it's a trusted choice for architects worldwide.

How is ALUCOBOND® PLUS different from regular ACP panels?

Unlike standard ACP panels that typically use a polyethene core, ALUCOBOND® PLUS is engineered with a mineral-filled fire-retardant core. This makes it much safer and compliant with international fire safety standards. It also provides superior flatness, long-term weather resistance, and a wide range of finishes, ensuring both safety and aesthetics in demanding architectural projects.

Is ALUCOBOND® PLUS suitable for both exterior and interior applications?

Yes! ALUCOBOND® PLUS is highly versatile. For exterior applications, these aluminium composite panels offer weather resistance, UV stability, and long-lasting performance. Indoors, they enhance aesthetics with sleek, lightweight panels. With a wide variety of colours and finishes, ALUCOBOND® PLUS is ideal for facades, signage, ceilings, and decorative interiors.

Is ALUCOBOND® PLUS fire-resistant?

Absolutely. ALUCOBOND® PLUS is manufactured with a fire-retardant mineral-filled core, making it far more fire-resistant than regular ACP panels. This provides enhanced safety for buildings while maintaining design freedom and durability.

Which fire safety standards does ALUCOBOND® PLUS comply with?

ALUCOBOND® PLUS complies with international fire safety standards, including EN 13501-1 (Euroclass B-s1,d0), ASTM E84, and other globally recognized benchmarks. This makes it a preferred option for high-rise and public buildings, where safety is critical, while also ensuring superior performance compared to conventional aluminium composite panels.

What are the key benefits of using ALUCOBOND® PLUS in architecture?

The benefits of ALUCOBOND® PLUS ACP panels include:

- Excellent fire safety

- Outstanding weather resistance

- Superior flatness

- Lightweight yet strong structure

- Easy processing and installation

- Wide range of colours and finishes

Architects value ALUCOBOND® PLUS for its design flexibility, whether used in bold facades or sleek interiors, while also ensuring long-term durability and safety.

Is ALUCOBOND® PLUS easy to process and install?

Yes, these aluminium composite panels are designed for easy fabrication. They can be cut, bent, drilled, and shaped with standard tools. Their lightweight yet rigid composition reduces installation time and labour costs, making them ideal for modern cladding and curtain wall systems.

What thicknesses are available for ALUCOBOND® PLUS panels?

ALUCOBOND® PLUS is available in 3mm, 4mm, and 6mm thicknesses, with 4mm being the most commonly used for facades. This variety allows flexibility for projects, lightweight panels for interiors and thicker, more robust ACP panels for exterior cladding systems.

What are the recommended installation methods for ALUCOBOND® PLUS?

Recommended methods for installing these aluminium composite panels include routed-and-returned systems, cassette fixing, tray systems, riveted or screwed fixing, and adhesive bonding. ALUCOBOND® PLUS also integrates seamlessly with ventilated facade systems, ensuring both long-term stability and aesthetic appeal.

How lightweight is ALUCOBOND® PLUS compared to other cladding materials?

ALUCOBOND® PLUS is significantly lighter than solid aluminium sheets or concrete cladding while offering excellent rigidity and durability. As ACP panels, they reduce the structural load on buildings, simplify handling during installation, and lower overall project costs, without compromising safety or aesthetics.