Known across the world as ‘the original’ ALUCOBOND® has been the market leader in aluminium composite panels since 1969.

ALUCOBOND® is known for its incredible properties, such as extraordinary flatness, a large variety of colours, and perfect formability. It has been developed to be both a rigid and flexible fascia material for architecture and is extremely weatherproof, impact-resistant, and break-proof, vibration-damping, and ensures easy and fast installation.

As a light composite material consisting of two aluminium cover sheets and a plastic core, this incredibly versatile product is also preferred in areas other than architecture – such as corporate design – and is widely used in industry and transportation.

ALUCOBOND® sold over a million sq.m of cladding material worldwide and has been awarded with numerous international prizes.

It is also used extensively by organizations planning to create a new corporate design for retail chains, car showrooms, banks, petrol stations, etc.

| CHARACTERISTICS |

ADVANTAGES |

|---|---|

| Low weight, high rigidity, perfect flatness | Low cost for substructures and fasteners, Smooth handling on the site |

| Large variety of colours | Unlimited planning and design |

| Weatherproof | Supplied ready to install |

| Vibration-damping | No additional sound-damping needed |

| Can easily be folded and bent | Simple processing using conventional tools |

| Large panel sizes, fast installation, pre-fabricated panels | Short construction times, adherence to schedules, low cost |

ALUCOBOND® perfectly adapts to a building’s contours, flowing elements. It is the combination of formability, flatness, stability, and weather resistance that characterizes this material. Due to its composite structure, ALUCOBOND® can take on many different shapes. Though both stable and flat ALUCOBOND® can be perfectly formed without any loss to its rigidity.

Lightness meets rigidity

The composite structure of ALUCOBOND® means it has an impressive strength to weight ratio, even when compared to large panel sizes. Despite its low weight – which makes ALUCOBOND® easy to transport and handle – its rigidity helps maintain its shape and flatness, even when exposed to extreme temperature changes.

Sustainability

3A Composites: Environment, Safety, and Quality

3A Composites is the parent company of ALUCOBOND® and is recognized across the globe as one of the leaders in the field of sustainability. Its reputation is spread far and wide, including among other diversified producers and raw material processing companies around the world.

The company’s unflinching commitment to sustainability – along with taking the needs of all key groups into account – enables it to make decisions of the highest economic, social, and ecological value. 3A Composites also commits to continuous self-improvement programs for environmental protection, many of which exceed government regulations.

Environment, Safety and Quality

Today 3A Composites is recognized worldwide as one of the leading companies in the field of sustainability – in fact not only within its own branch but also among other diversified producers and raw material processing companies throughout the world. 3A Composites’s commitment to sustainability enables the company to make decisions that create the highest economic, social and ecological value, by taking the requirements of all the relevant groups into consideration.

The company commits to continuous self improvement programs for environmental protection, many of which exceed government regulations. 3A Composites continues to serve as a global leader in this field.

During the life cycle of ALUCOBOND® composite panels, no substances containing CFC are set free at any time. The core material does not contain any nitrogen, chlorine or sulphur. Therefore, selecting ALUCOBOND® for projects which require environmental-friendly materials is literally a natural choice.

ALUCOBOND® Lifecycle

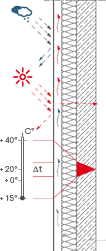

Over decades of use in a rear-ventilated cladding system, ALUCOBOND® protects a building from weathering and the harmful effects of industrial and environmental pollution. It also acts as a barrier against solar radiation; the ventilated space between the ALUCOBOND® panels and the wall or the thermal insulation reduces heat transmission.

ALUCOBOND® also protects the wall of a building from high and rapid temperature changes; moisture can pass through the wall, yet the building structure remains dry.

During the lifecycle of ALUCOBOND® composite panels, no substances containing CFC are set free at any time. The core material does not contain any nitrogen, chlorine, or sulfur – therefore, it is the perfect choice for projects which require environmental-friendly materials.

The major advantages

- There are lower maintenance costs

- There is the long-term preservation of the building’s structure

- During winter there are major savings in heating costs

- In summer there are major savings in air-conditioning costs

- There is a reduction of thermal expansion

- There is a reduction in crack formation

Recycling

ALUCOBOND® is fully recyclable. Both the core material and the aluminum cover sheets can be used in the production of new material.